Transforming Waste into Energy: How to Set Up a Pyrolysis Plant?

As DOING receives many inquiries from customers at home and abroad about how to set up a pyrolysis plant to transform waste into energy every day, in this paper we will take a look at what preparatory works should be done before setting up a pyrolysis plant to make the pyrolysis plant run smoothly.

1. Access to local market waste material supply sources

Before setting up a pyrolysis plant, it is advisable to find a stable source of raw materials and ensure a reliable supply of raw materials. Waste tire, waste plastic, waste rubber, oil sludge, coal tar oil residue, alumnium plastic and so on, which all are available for pyrolysis plants. You can look for scrap tire traders, or other solid waste treatment centers to seek a steady supply of these waste materials.

(Noted: PVC and PET plastics are not suitable for pyrolysis plants)

Multiple raw materials of the pyrolysis plant

Multiple raw materials of the pyrolysis plant

2. Make a market survey on the final product of pyrolysis plant.

With the pyrolysis plant, we can transform waste into energy. Various raw materials can produce various final products. For waste plastics, we can get carbon black and fuel oil; for waste tires, we can also get steel wires. All these final products have wide uses in large markets.

Fuel oil can be widely used in boiler factories, cement factories, steel plants and other industrial heating fuels. And after further refining, the diesel derived from pyrolysis oil can also be used in some generators and heavy machinery. Carbon black can not only be processed into coal briquettes as heat energy, but also can be refined to make new tires, shoe soles and paints. And the steel wire obtained from waste tires can be sold directly as scrap steel.

Final products and applications of waste tire plastic pyrolysis

Final products and applications of waste tire plastic pyrolysis

Therefore, we need to make a market survey of the final products in advance, ensuring to sell these final products quickly and generate huge benefits.

3. Select a suitable pyrolysis plant

After determining the type and quantity of raw materials, we need to select a suitable pyrolysis plant to transform these waste into energy. The quality of the pyrolysis plant, processing capacity, and the service capacity of the manufacturer all affect the smoothness of setting up a pyrolysis plant.

DOING has been committed to developing pyrolysis plants for more than 13 years and has researched three types of pyrolysis plants: skid-mounted pyrolysis plant, batch type pyrolysis plant and fully continuous pyrolysis plant, which have their own advantages and processing capacities. If you have trouble selecting a suitable pyrolysis plant, just tell us your processing materials and production capacity, and DOING can provide you with detailed solutions based on your actual situation.

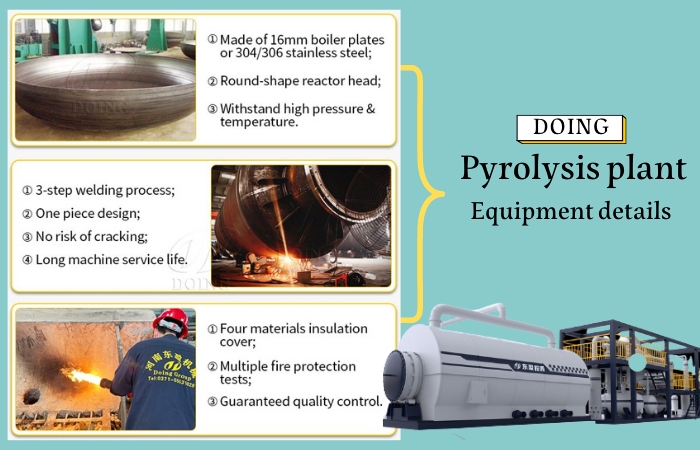

DOING pyrolysis plant details and advantages

DOING pyrolysis plant details and advantages

4. Find a piece of land of the right size

Selecting a suitable piece of land for a pyrolysis plant is crucial for its success.

For example, for a 10TPD waste pyrolysis plant, considering the working area of the pyrolysis plant, the storage of raw materials and finished products, etc., a piece of land of at least 500 square meters is required. In addition, the selected location needs to have convenient transportation for raw materials and finished products.

DOING has a professional technical team to provide you with comprehensive services from choosing suitable pyrolysis plant, construction site to building and installtion guidance, worker training,etc. If you are interested in transforming waste into energy or want to set up a pyrolysis plant, please contact us directly.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

DOING waste plastic pyrolysis plant adopts core technology and is made of one piece of welding. DOING company provides after-sales installation and maintenance services.

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- How can we turn plastic waste into green energy?

- Does it need to add catalysts in the tire plastic pyrolysis process?

- How do you purify tire plastic pyrolysis oil?

- What is the process of converting plastic to diesel?

- Do waste plastics need to be cleaned before pyrolysis?

- How can waste plastics be converted to fuel oil?

- Can you make oil from plastic? How do we turn waste plastic into oil?

- What does waste plastic to diesel recycling plant cost?

- How to make fuel and gas out of plastic waste?

- Can plastic bags be recycled into oil?

Leave a message

Mobile/Wechat/Whatsapp: