How can we turn plastic waste into green energy?

To turn plastic waste into green energy, waste plastic pyrolysis machine will be the best method, which is the high temperature pyrolysis reaction under anaerobic conditions, converting high molecular compounds into low molecular compounds.

DOING waste plastic pyrolysis machine for sale

DOING waste plastic pyrolysis machine for sale

During this pyrolysis process, waste plastics can be turned into green energy, like plastic pyrolysis oil, carbon black and combustible gas, which can generate double economic and environmental benefits while solving plastic waste.

The following is a brief introduction about the working process of turning plastic waste into green energy with a waste plastic pyrolysis machine:

1. Feeding: generally we have three feeding methods: manual feeding, feeding with conveyor belt and automatic feeding. The last feeding method has the highest working efficiency and is the most popular.

Auto-feeder of DOING waste plastic pyrolysis machine

Auto-feeder of DOING waste plastic pyrolysis machine

2. Heating: after feeding waste plastics into the pyrolysis reactor, heat the reactor to a certain temperature, the oil gas will come out.

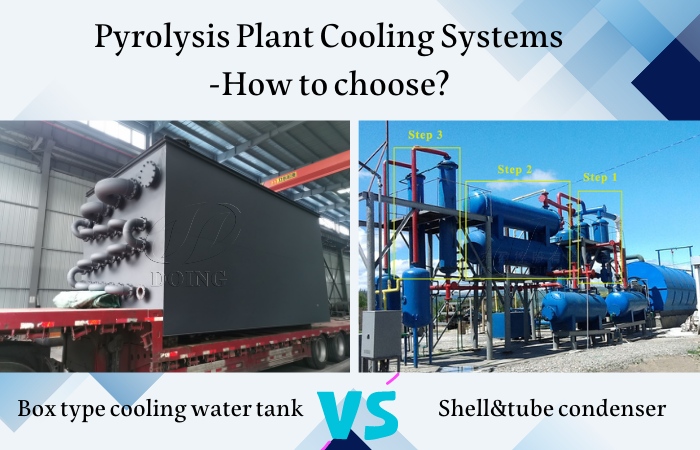

3. Cooling: when oil gas goes through the cooling system, the oil gas will be cooled into liquid oil. Here DOING can provide two types of cooling system: three-step cooling system and water tank cooling system, which both have great cooling effect. You can select them based on your situation.

Two cooling systems of DOING waste plastic pyrolysis machine

Two cooling systems of DOING waste plastic pyrolysis machine

4. Purifying: after obtaining the liquid plastic pyrolysis oil, the remaining exhaust gas needs to be purified to meet the emission standards. Here DOING equips the tail-gas cleaning system and desulfurization tower with the waste plastic pyrolysis machine, which can make full purification for the exhaust gas.

5. Collecting: finally, the purified gas will be transported to heat the pyrolysis reactor, and the obtained plastic pyrolysis oil and carbon black can be collected.

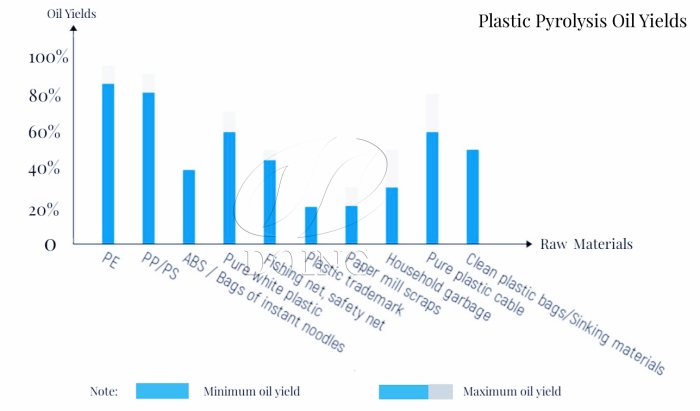

After the whole process, we can turn plastic waste into green energy, but one thing you need to note, not all plastics can be turned into green energy with the waste plastic pyrolysis machine, such as PET and PVC. Here I will make a display of the common plastics that can be turned into green energy with waste plastic pyrolysis machines and oil yield:

Oil yield of various waste plastics

Oil yield of various waste plastics

In addition, apart from the plastic waste, we can also recycle other solid waste to green energy, like waste tires, rubber, oil sludge, e-waste, etc. If you also want to obtain green energy from solid waste, just tell us your raw material, our sales manager will customize the detailed scheme for you.

Prev:What are the types of materials pyrolysis equipment can process?

Next:Does it need to add catalysts in the tire plastic pyrolysis process?

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

Leave a message

Mobile/Wechat/Whatsapp: