What is the Most Profitable Plastic Recycling Way?

In recent years, with the rapid development of the plastic industry, the issue of plastic waste ("white pollution") has grown increasingly severe, posing a significant challenge to the global environment and human health. Traditional plastic recycling ways face numerous limitations, such as low recycling rates and poor recyclability of mixed plastics. Against this backdrop, plastic pyrolysis te chnology has emerged as a highly promising and profitable wasye plastic recycling solution.

Waste plastic recycling pyrolysis technology

Investment and Profit Analysis of Plastic Pyrolysis

Equipment Investment: As the core of plastic pyrolysis, equipment costs are a significant portion of the initial investment. However, with continuous advancements in pyrolysis technology and the scaling of production, equipment costs are gradually decreasing.

Plastic pyrolysis plant setting up cost

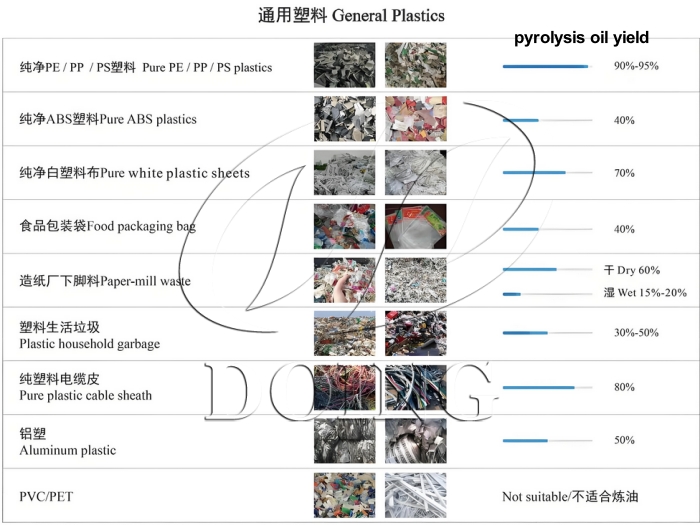

Raw Material Costs: One of the advantages of plastic pyrolysis is the diverse range of waste plastic raw materials available. Waste plastic sources include discarded plastic products, industrial plastic waste, and plastic packaging. Most plastics(except PVC and PET), such as PE (polyethylene), PP (polypropylene), PS (polystyrene), and their mixtures, are excellent materials for pyrolysis. These plastics yield high oil rates during pyrolysis, with pure PE, PP, and PS achieving oil yields exceeding 70%.These materials are relatively inexpensive and widely available, ensuring a stable and low-cost supply of raw materials.

General plastic pyrolysis oil yield

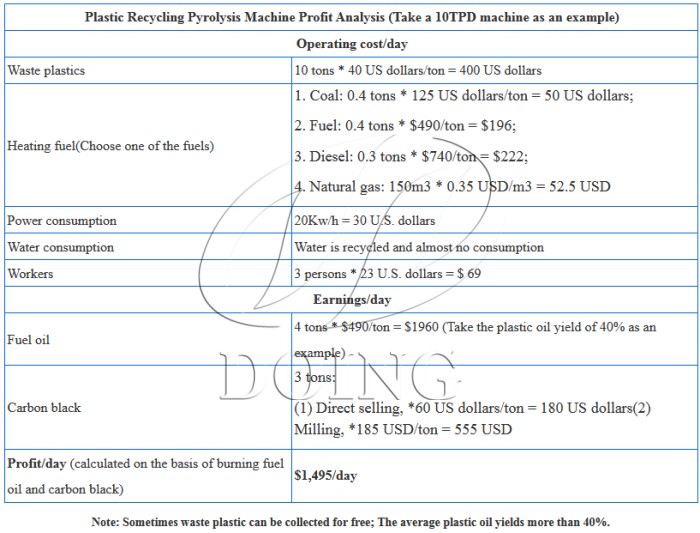

Profit Potential: The profits from plastic pyrolysis mainly come from the sales of pyrolysis oil and carbon black, as well as the recycling of tail gas. Pyrolysis oil serves as a high-calorific heating fuel that can be used in industrial boilers, kilns, power generators, and more. After distillation and refining, it can be converted into non-standard diesel, powering heavy machinery, construction equipment, trucks, tractors, and other vehicles. According to market research, the price of pyrolysis oil typically ranges from 300 to 500 per ton, while refined diesel can fetch even higher prices. Carbon black produced during pyrolysis can be processed into fuel briquettes or used as a raw material in the rubber industry. Its market price generally falls between 900 and 1200 per ton. Additionally, the tail gas generated during pyrolysis can be recycled to fuel the pyrolysis reactor, reducing energy consumption and lowering production costs.

10TPD plastic pyrolysis plant profit analysis

Payback Period: Based on the cost and revenue analysis above, a pyrolysis plant processing 10 tons of plastic waste daily can generate profits of approximately 1200–1700 per day. With a reasonable equipment investment, the payback period is relatively short. As environmental policies tighten and demand for renewable energy grows, the market potential for plastic pyrolysis is expected to expand further.

Comparative Analysis of Plastic Pyrolysis and Other Recycling ways

Mechanical recycling: Mechanical recycling involves processes such as crushing, washing, and remelting plastic waste into plastic products. However, this way is limited to specific types of plastics and requires high-purity raw materials. It struggles with mixed plastics and results in inferior quality recycled products with limited applications and low economic value. In contrast, plastic pyrolysis can handle a wider variety of plastics, including mixed plastics, and produces high-value diesel, offering better economic returns.

Chemical recycling: Chemical recycling ways, such as depolymerization, convert plastic waste into monomers or other chemical products. While these ways have high recycling rates and produce high-quality products, they demand stringent raw material requirements, complex processes, and high costs. Pyrolysis technology, on the other hand, boasts simpler processes, lower costs, and relatively higher economic benefits.

DOING plastic pyrolysis plant manufacturer

In summary, plastic pyrolysis is currently one of the most profitable plastic recycling ways. It not only can improve plastic pollution but also generates significant economic returns. Compared to other waste plastic recycling ways like mechancial and chemical recycling, it offers distinct advantages. If you want to engage in profitable plastic recycling pyrolysis business, welcome to send us your inquiry. Henan Doing will be glad to share more professional guidances.

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

Leave a message

Mobile/Wechat/Whatsapp: