What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

Plastic waste has become one of the most pressing environmental challenges of our time. Traditional plastic recycling methods, though vital, have limitations and fail to address the complexity of modern plastic waste streams. However, plastic pyrolysis—advanced thermal decomposition technology—offers groundbreaking solutions.

Waste plastic pyrolysis technology

Compared with traditional plastic recycling methods, plastic pyrolysis technology has the following significant benefits and technological breakthroughs:

Broader Range of Processable Plastics

Traditional recycling is limited to certain types of plastics like PET, HDPE, and PP. Contaminated or multi-layered plastics often end up in landfills.

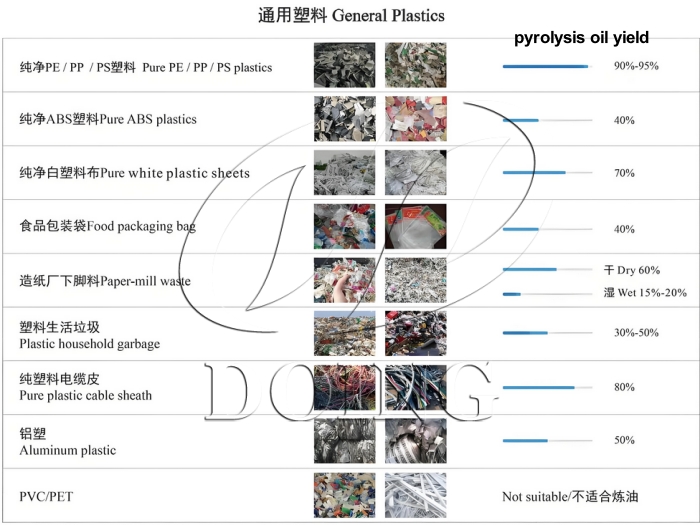

Plastic pyrolysis, by contrast, can handle a wide variety of plastics like pure PP/PE/PS, plastic sheets, paper-mill waste, plastic cable sheath, including mixed and contaminated materials. This versatility ensures that even plastics otherwise labeled as 'non-recyclable' can be transformed into valuable products like pyrolysis oil and carbon black, thereby reducing landfill dependency.

Waste plastic pyrolysis raw materials and oil yield

High-Quality Output

Traditional Recycling often results in lower-quality materials due to degradation during processing (downcycling).

Plastic pyrolysis technology converts waste plastic into high-value pyrolysis oil and carbon black and syn-gas. Pyrolysis oil can be used directly in the petrochemical industry to manufacture new plastics or as an efficient alternative fuel for boiler heating in transportation and energy sectors, cement plants, steel mills, and other applications. Carbon black is widely used in rubber products (such as tires and seals) as well as in the coatings and pigments industries as a reinforcing agent and functional additive. As for the syngas generated in the plastic recycling pyrolysis process, on the one hand, you can use it as fuel to directly heat reactors of plastic pyrolysis plants or other boilers. On the other hand, you can store it or use it to generate electricity.

This waste-to-resource approach not only maximizes the economic value of plastic waste but also creates a new path for sustainable development for industrial enterprises while reducing environmental pollution.

Final products and applications from waste plastic pyrolysis plant

Lower Energy Consumption

Traditional recycling requires significant energy inputs for sorting, cleaning, and reprocessing plastics.

Plastic pyrolysis operates in an oxygen-free environment, breaking down plastics thermally. Once optimized, the pyrolysis process can achieve considerable energy savings compared to mechanical recycling methods. Additionally, energy recovery systems within pyrolysis plants allow the reuse of excess thermal energy, further enhancing efficiency.

Plastic pyrolysis tail gas recovery

Reduced Environmental Impact

Traditional recycling methods generate wastewater and air emissions during washing and sorting processes, contributing to environmental pollution.

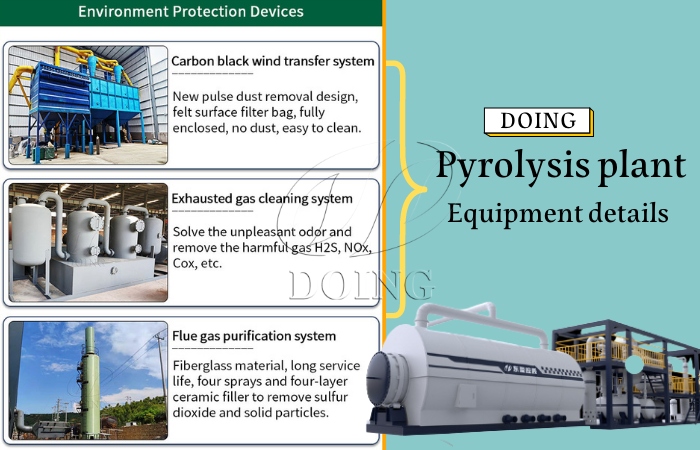

Plastic pyrolysis, when conducted in well-designed systems, produces fewer emissions and can operate as a closed-loop process, minimizing waste. While pyrolysis does create by-products like char and syngas, pyrolysis plants incorporate advanced filtration and gas-cleaning systems to ensure compliance with environmental standards. This enables pyrolysis to be both efficient and environmentally sustainable.

DOING plastic pyrolysis plant environment protection devices

In a world grappling with escalating plastic pollution, plastic pyrolysis represents a game-changing plastic recycling solution with multiple benefits. Its ability to process a broad range of plastics, produce high-value outputs, conserve energy, and reduce environmental impact positions it as a superior alternative to traditional plastic recycling methods.

DOING waste plastic pyrolysis plant manufacturer

Henan DOING Company has been dedicated to the manufacture of plastic pyrolysis machinery. With mature technology and sophisticated processes, we can tailor efficient pyrolysis solutions to meet your plastics processing and recycling needs. We can provide you with a full service for implementing plastics recycling pyrolysis projects, helping you maximize benefits!

Prev:Is pyrolysis better than incineration?

Next:How pyrolysis technology helps reduce the carbon footprint?

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

Leave a message

Mobile/Wechat/Whatsapp: