What are the machines for plastic recycling?

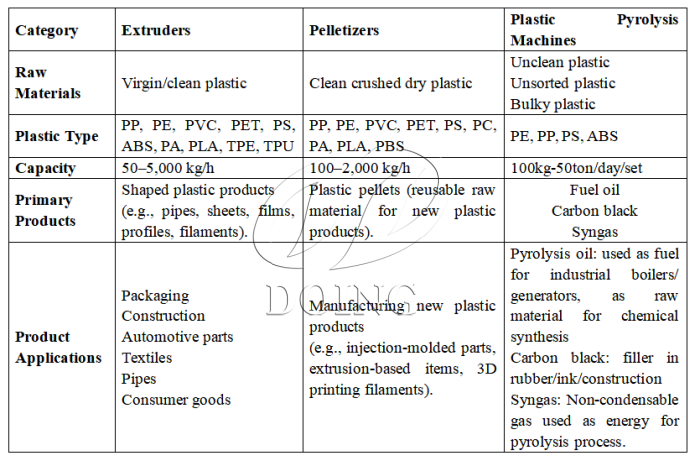

There are many different types of machines to recycle plastic, like extruders, pelletizers, pyrolysis machine, all of which have different characteristics as follows:

Plastic recycling machine

Plastic recycling machine

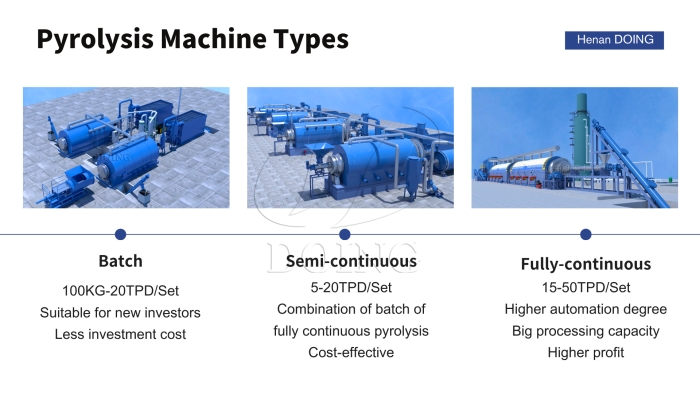

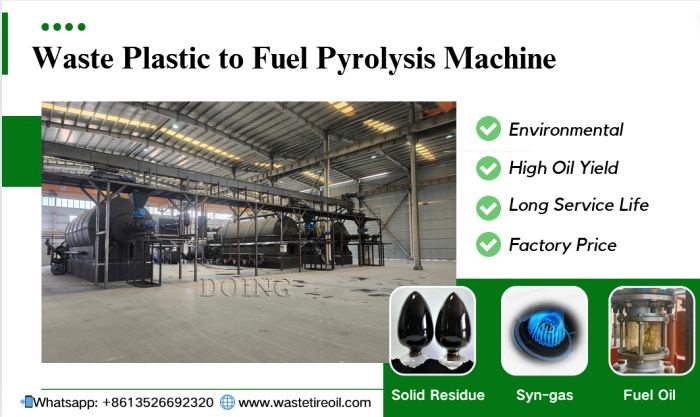

Compared with extruders, pelletizers, pyrolysis machines offer a simpler and more efficient alternative for plastic recycling. DOING has designed three types of plastic recycling pyrolysis machine: batch type, semi-continuous type and fully-continuous type, recycling waste plastics into valuable fuels, carbon black and syngas. Below are some of the machines commonly involved in plastic recycling through pyrolysis:

DOING recycling waste plastic pyrolysis machine

DOING recycling waste plastic pyrolysis machine

1. Plastic Shredder

If you choose a semi-continuous type and fully continuous type pyrolysis machine, the first step requires using a plastic shredder to break down large plastic waste (such as bottles, bags, or containers) into uniform, smaller pieces or particles, which makes the material easier to handle in subsequent stages.

DOING recycling waste plastic shredder machine

DOING recycling waste plastic shredder machine

If you choose batch type plastic pyrolysis machine, there is no need to break down the plastic, just throw the plastic directly into the pyrolysis reactor.

2. Pyrolysis Reactor

Heats the plastic in an oxygen-free environment. Inside the reactor, temperatures range between 350°C and 500°C depending on the plastic type, causing the material to break down into simpler hydrocarbons without burning. This produces gaseous, liquid, and solid byproducts.

DOING recycling waste plastic pyrolysis machine

DOING recycling waste plastic pyrolysis machine

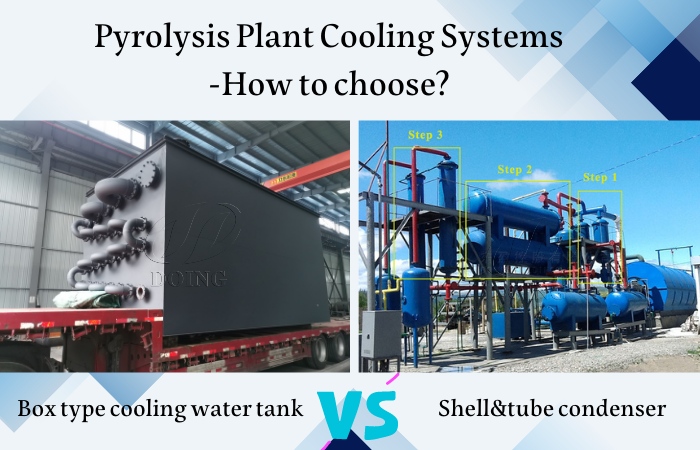

3. Condenser System

Following pyrolysis, the resulting oil gas then flows into a condenser system, where it is cooled and liquefied into diesel, which uses multi-stage cooling and has an oil and gas recovery rate of up to 99%.

Condenser System of DOING plastic pyrolysis machine

Condenser System of DOING plastic pyrolysis machine

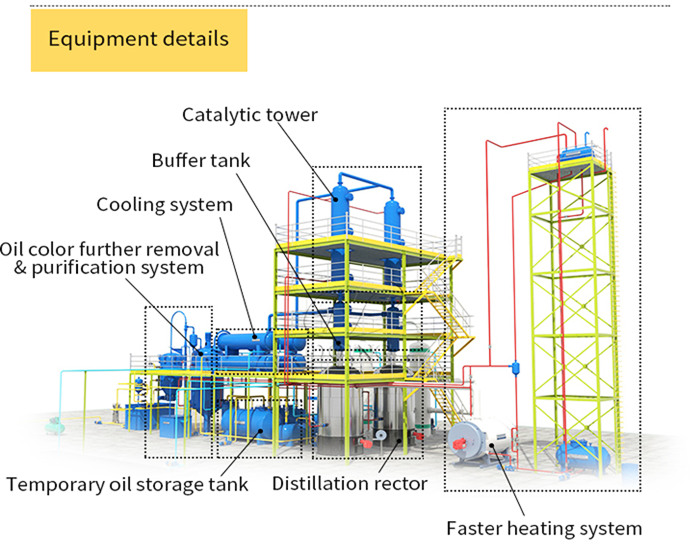

4. Distillation Machine

If you want to obtain a better quality fuel, it can be further refined, and the distillation machine processes the condensate into diesel for industrial use.

DOING plastic pyrolysis oil distillation machine

DOING plastic pyrolysis oil distillation machine

5. Tail Gas Treatment Device

The non-combustible and non-condensable gases are purified by the tail gas treatment device designed by DOING to meet the environmental emission standards and are discharged.

Tail Gas Treatment Device of DOING plastic pyrolysis machine

Tail Gas Treatment Device of DOING plastic pyrolysis machine

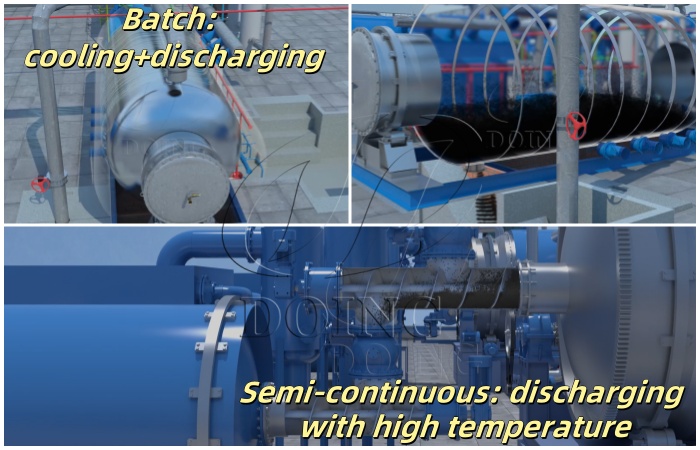

6. Carbon black Collection Machine

For the carbon black obtained after pyrolysis, the batch type plastic pyrolysis reactor can use the front slag discharge, the side slag discharge or the rear slag discharge method to discharge the carbon black after cooling. The semi-continuous type plastic pyrolysis reactor discharges the carbon black into a small reactor to achieve high-temperature slag discharge. The fully continuous type plastic pyrolysis reactor uses a multiple cooling system to directly discharge low-temperature carbon black.

Carbon black Collection Machine of DOING plastic pyrolysis machine

Carbon black Collection Machine of DOING plastic pyrolysis machine

More importantly, due to the particularity of some plastics, wax is easily deposited during the pyrolysis process. DOING plastic recycling pyrolysis machines provide a wax removal device. Whether you choose a batch type, semi-continuous type, or fully-continuous type, each machine is designed to maximize resource recovery while minimizing environmental impact and making profits. Welcome to contact us for more details about DOING plastic recycling machine.

Prev:What is the most common method for recycling plastics?

Next:Can plastic be converted to diesel ?What machine can DOING provide?

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

Leave a message

Mobile/Wechat/Whatsapp: