How can waste plastics be converted to fuel oil?

Using pyrolysis plants to convert waste plastics into oil is a proper and profitable plas treatment way. It can solve the pollution problems caused by waste plastics and obtain the pyrolysis fuel oil, which can be used as an alternative energy to industrial fuel oil.

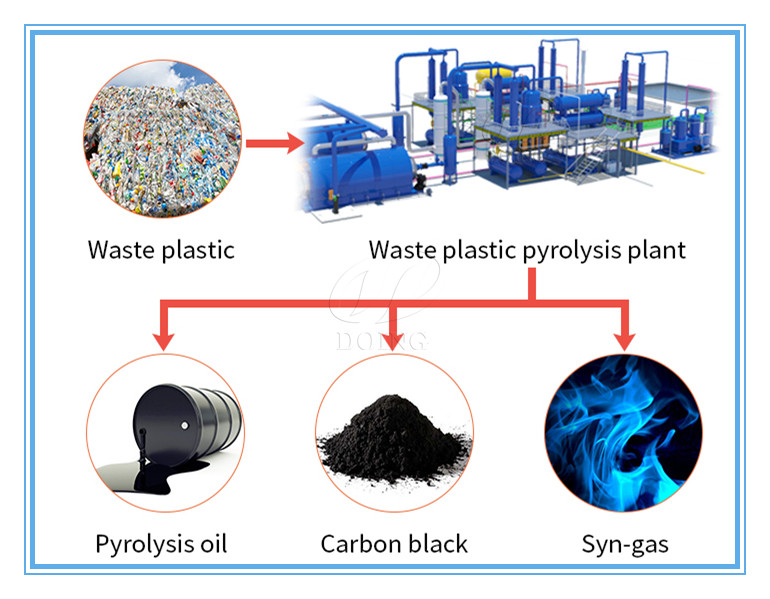

Plastics to oil pyrolysis plant picture

Plastics to oil pyrolysis plant picture

The recycling process of waste plastics being converted of fuel oil mainly includes the following steps:

●1st step: feed the waste plastics into the pyrolysis reactor;

●2nd step: heat the pyrolysis reactor and when the temperature rises to about 120 degrees, the plastic will be gradually cracked into oil gas;

●3rd step: the produced oil gas will enter the condensing system cooling into liquid plastic pyrolysis fuel oil, storing in the temporary oil tank. And the non-condensable gas can be used as the pyrolysis treactor heating fuel after purification to save operation cost.

●4rd step: after the pyrolysis fuel oil production process is finished, we can discharge and collect the carbon black.

The 3D animation of DOING pyrolysis plant converting waste plastic into oil:

After the whole waste plastic to oil pyrolysis process, we can obtain about 30-90% pyrolysis fuel oil. And the obtained pyrolysis fuel oil has wide uses:

The applications of plastics pyrolysis oil

The applications of plastics pyrolysis oil

1. It can directly replace fuel oil for industrial or boiler heating, such as cement plants, ceramic factories, power generation plants, steel plants, glass plants, etc.;

2. It can be refined into diesel for diesel combustion and power plants, agricultural machinery, etc.

Note: The detailed oil yield of converting plastic to oil is mainly influenced by waste plastic types and the pyrolysis technology.

DOING Company has been engaged in the R&D and exporting of pyrolysis plants for more than 12 years. With the advantages of safety, energy saving, high pyrolysis rate and high oil yield, our pyrolysis plants have been hot sales in 100+ countries and won wide recognition from customers. If you are interested, please feel free to contact us to inquire about waste plastic pyrolysis plants.

Prev:Do waste plastics need to be cleaned before pyrolysis?

Next:Can you make oil from plastic? How do we turn waste plastic into oil?

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

Leave a message

Mobile/Wechat/Whatsapp: