Unlocking millions annual profits through continuous pyrolysis plant

In today's rapidly evolving landscape of sustainability and innovation, converting waste into valuable resources is far more than an environmental imperative—it's a blueprint for substantial financial success. For entrepreneurs and investors eyeing lucrative opportunities in green energy and waste management, continuous pyrolysis plants offer a path to generating millions in annual profits. This innovative technology doesn't just recycle; it converts abundant waste materials like scrap tires and plastics into high-value products, fueling a circular economy while delivering exceptional returns on investment.

DOING fully continuous pyrolysis plant characteristics

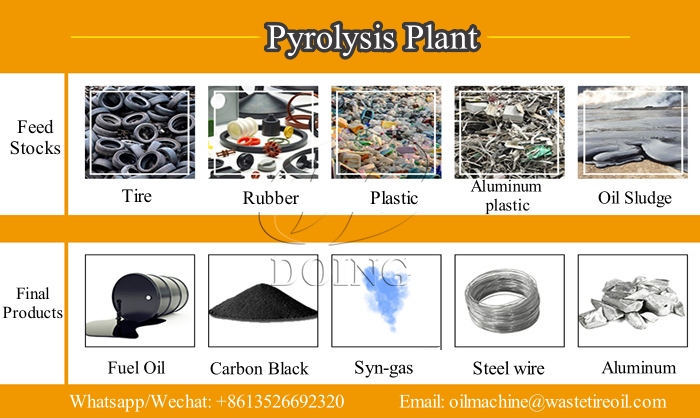

Pyrolysis involves heating organic waste materials to elevated temperatures, causing them to vaporize and decompose without combustion. The resulting vapors are cooled and separated into high-value byproducts, creating multiple revenue streams from a single operation:

Fuel Oil (40-50% yield): A versatile liquid fuel for industrial boilers, generators, and even refined into diesel. Market price: $400-600 per ton.

Carbon Black (30-35% yield): Used in tire manufacturing, inks, and plastics. Market price: $500-800 per ton.

Steel Wire (10-15% yield from tires): Recovered and sold as scrap metal. Market price: $200-300 per ton.

Combustible Gas (10-15% yield): Non-condensable gases like syngas, which can be recycled to heat the reactor, slashing energy costs.

Profit Analysis: A 30-ton/day plant operates 300 days/year, processing 9,000 tons annually. At current market rates, this yields:

Fuel oil: 4,000 tons × $500/ton = $2 million

Carbon Black: 2,700 tons × $600/ton = $1.62 million

Steel Wire(tire): 900 tons × $250/ton = $225,000

Total gross revenue: ~$3.845 million

Final products of continuous pyrolysis plant

The Superior Advantages of Continuous Pyrolysis Plants

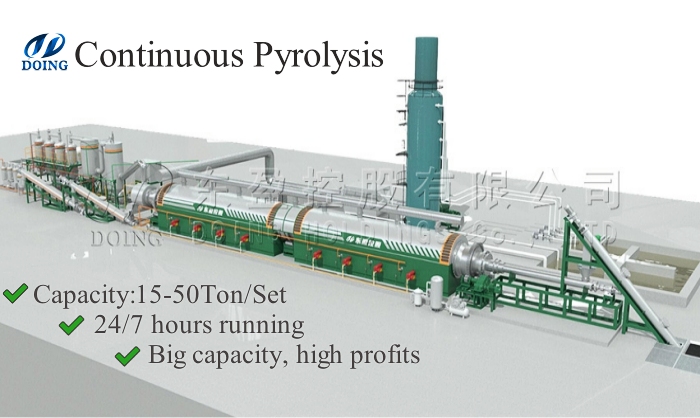

1. Maximized Throughput and Consistent Output

A single DOING continuous pyrolysis plant is engineered to process significant volumes daily, ranging from 15 to over 50 tons of feedstock such as scrap tire powder. This high-capacity, continuous processing capability ensures a maximized daily output of marketable products. Consistent, high-volume production is the fundamental driver of substantial revenue generation over the year.

DOING continuous pyrolysis plant features

2. Uninterrupted Operation for Enhanced Production Efficiency

Unlike legacy systems that demand repeated cycles of startup, processing, and shutdown—resulting in significant idle time—DOING continuous plants employ advanced screw conveyor mechanisms for automated, sealed feeding and discharging. This enables non-stop operation, dramatically increasing overall throughput and minimizing lost productivity.

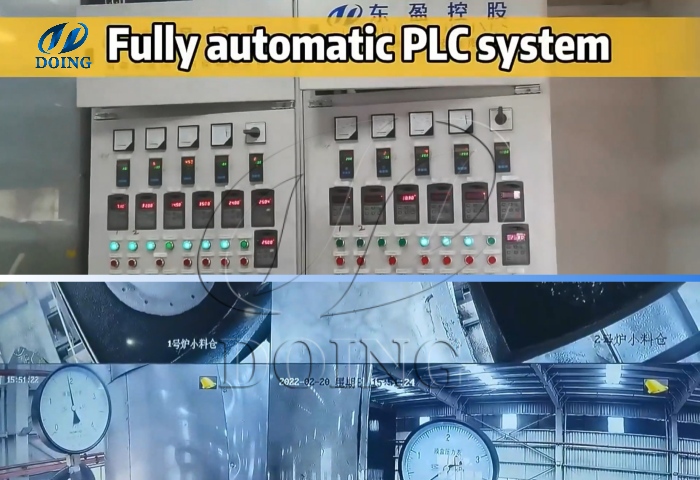

3. Advanced Automation to Slash Labor Expenses

Integrated with a advanced PLC system, DOING continuous pyrolysis plants offer full-process automation, including real-time monitoring, precise temperature and pressure regulation, and built-in error detection with instant alarms. This sophistication reduces the need for a large workforce, requiring only a minimal team of skilled operators to oversee the entire facility. By cutting labor requirements substantially, automation lowers one of the largest ongoing expenses in waste processing. The resulting cost savings flow directly to the bottom line, allowing more of the generated revenue from byproducts to become pure profit. Additionally, the system's reliability ensures consistent yields, avoiding revenue dips from operational hiccups.

DOING continuous pyrolysis plant PLC system

4. Energy Self-Sufficiency Through Gas Recycling

A standout feature of DOING's continuous pyrolysis plants is the efficient capture and purification of non-condensable gases produced during the process. These gases are recycled back into the reactor as a clean, free fuel source, powering the heating requirements without reliance on external energy inputs. Reducing fuel costs—often a major budgetary drain—frees up capital that would otherwise be spent on purchased energy.

Continuous pyrolysis plant syngas recycling systems

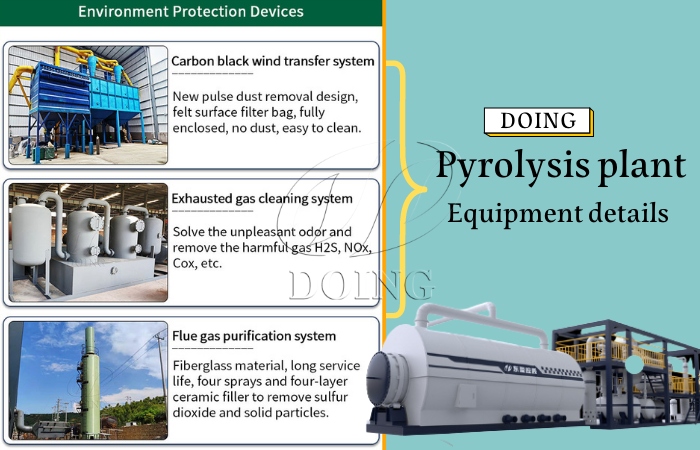

5. Sealed Systems for Environmental Compliance and Market Differentiation

DOING continuous pyrolysis plants incorporate fully enclosed feed and discharge processes, preventing dust, emissions, and odors from escaping. Equipped with advanced gas filtration and scrubbing technologies, DOING continuous pyrolysis plants adhere to stringent international environmental standards, ensuring safe, low-impact operations. Compliance avoids hefty regulatory fines, legal disruptions, and unplanned shutdowns that could erode profits.

DOING continuous pyrolysis plant environment protection devices

The true power of DOING's continuous pyrolysis plants lies in their synergistic design, where multiple advantages converge to create a robust profitability model. Revenue is generated through the diverse sale of high-demand byproducts—fuel oil for energy markets, carbon black for manufacturing, steel wire for recycling, and even syngas for internal use. Meanwhile, automation, energy recycling, and efficient operations collectively minimize key costs: labor, fuel, maintenance, and compliance-related expenses.

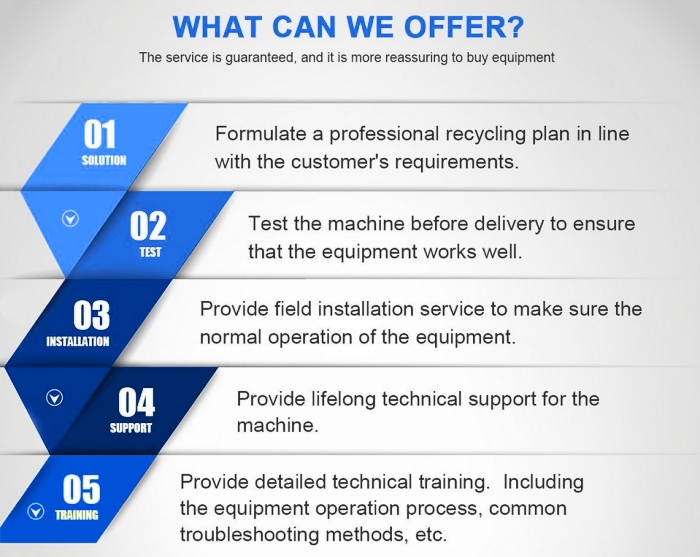

DOING continuous pyrolysis plant manufacturer services

At DOING Company, we are dedicated to empowering businesses with innovative pyrolysis solutions that blend profitability and sustainability. With years of expertise in designing and deploying continuous plants worldwide, we offer comprehensive support—from customized feasibility assessments to installation, training, and ongoing maintenance.

Prev:How Much is One Ton of Waste Plastic? Unlock Profit in Waste Plastic With Pyrolysis Machine

Next:Stop Losing Money on Plastic Landfill Disposal | Pyrolysis Profit Solutions

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line