What are the steps to start a pyrolysis plant in Australia?

Over the past 13 years, countless Australian clients have contacted DOING about pyrolysis projects in Australia. Here, I will write about how to start a pyrolysis plant in Australia and what steps are required.

Before starting a pyrolysis plant in Australia, we should first understand the current status and industry prospects of the pyrolysis project in local.

Waste tires for recycling in Australia

Waste tires for recycling in Australia

First of all, because Australia has accumulated thousands of waste tyres/plastic waiting to be managed, these waste tyres plastic are not allowed to be burned or disposed of through landfills, and the waste is even free in Australia. Secondly, the local government in Australia encourages people to dispose of waste tyres plastic in a highly environmentally friendly way, and people can get rebates from the government for waste tire disposal. To do waste tire/plastic pyrolysis project business in Australia, raw materials are sufficient, the price is cheap, and the profit is much higher than in other parts of the world. As far as I know, there are quite a few Chinese people in Australia doing waste tyre plastic pyrolysis business and making a lot of money.

Knowing the status of the waste tyre plastic pyrolysis project, then what steps are needed to start a pyrolysis plant in Australia, DOING group will give you some guidance and suggestions.

Step1: Secure a steady supply of waste tyres/plastic for long-term development and continued profitability. Maybe you can go to some local garbage recycling stations or auto repair shops to find raw materials, and determine the monthly or daily supply.

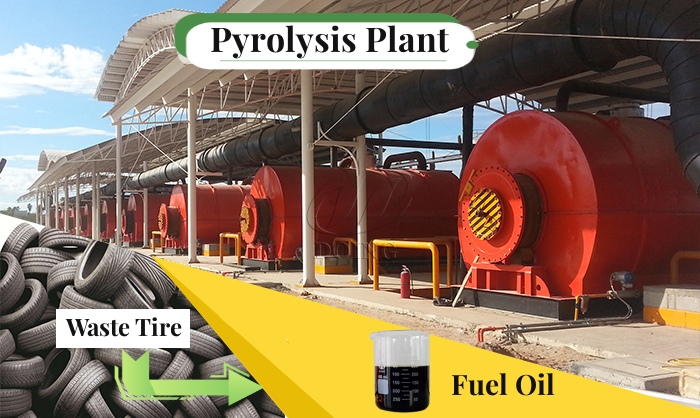

DOING waste tire pyrolysis machine

DOING waste tire pyrolysis machine

Step 2: The most important thing is to choose a good waste tyre/plastic recycling pyrolysis machine supplier to get environmentally friendly machines. The environmental standards in Australia are very high, and if you install pyrolysis machines that have a bad impact on the environment, it will cause you many serious problems. DOING pyrolysis machines are equipped with environmental protection devices, such as circulating water cooling systems to ensure no water pollution; desulfurization tower and tail gas deodorization device to ensure that the tail gas can meet the Australian emission standards; fully enclosed carbon black wind transfer system to ensure no dust pollution.

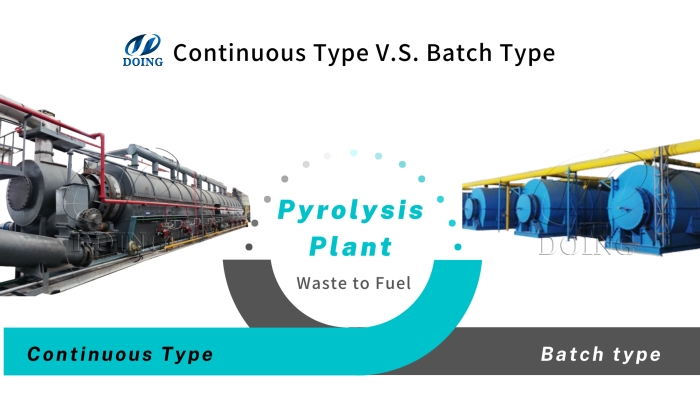

DOING batch & continuous type pyrolysis machines

DOING batch & continuous type pyrolysis machines

Besides, according to the daily supply of raw material, determine which type or capacity of machine to choose. DOING has batch type(100/500kg, 1/2/5/10/12/15/18/20t/d) and continuous type( 15/20/30/40/50t/d)pyrolysis machines can be chosen.

Step 3: Different processing capacity of pyrolysis machines takes up different areas. After selecting the machine, determine the location and area of the plant according to the specifications of the pyrolysis machine. An open field is fine, and a closed building of the right height is even better.

Step 4: Purchase and install waste tyre/plastic recycling pyrolysis machine. DOING has engineers provide installation and operation guidance services. If you choose us, during the installation of the machine, we will send engineers to carry out installation and commissioning of the machine onsite.

The installation & operation manual of DOING pyrolysis plant

The installation & operation manual of DOING pyrolysis plant

Step 5: Before the pyrolysis plant starts to operate, some operation training is required, and we will provide instruction manuals and videos, to give you some reference for workers training.

Up to this step, the pyrolysis plant can basically start to operate. If you are interested in the waste tyre/plastic pyrolysis business in Australia, please feel free to send your inquiry to DOING pyrolysis machine manufacturer, then DOING’s professional business managers will contact you and provide suitable assistance.

Prev:What's the recycling process of aluminum plastic pyrolysis plants?

Next:What is the estimated life expectancy of pyrolysis plant?

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

Leave a message

Mobile/Wechat/Whatsapp: