DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

DOING waste plastic pyrolysis plant adopts core technology and is made of one piece of welding. DOING company provides after-sales installation and maintenance services.

In fact, we also have a small waste tyre pyrolysis plant that can be used for testing or handling a small number of tyres. This small waste tyre pyrolysis plant is popular with customers in developed countries.

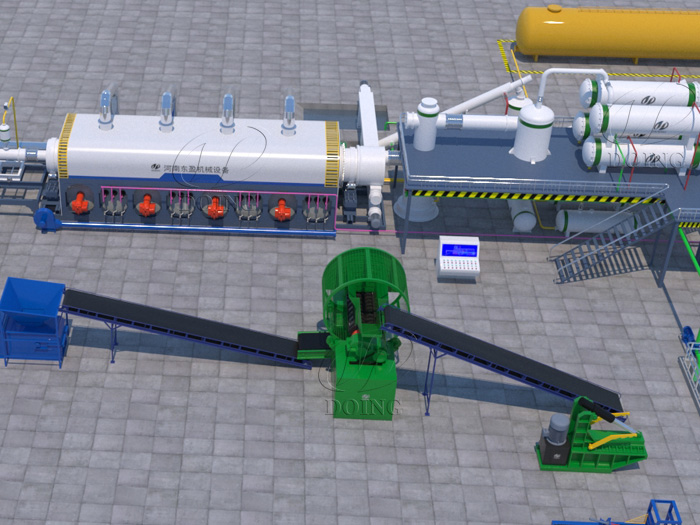

Continuous waste plastic recycling machine is a significant improvement on the existing intermittent waste plastic recycling machine at home and abroad. This continuous waste plastic recycling machine has a life span of five to six years longer than the i

Waste tire recycling pyrolysis plant can decompose the waste tire into fuel oil, carbon black and steel wire. Waste tire recycling pyrolysis plant is developed and produced by DOING machinery co., ltd. according to the principle of waste tire pyrolysis in

Waste plastic to oil machine is able to heat waste plastics through high temperature crack into oil, non-condensable gas and carbon black.Waste plastic pollution was even once called "white pollution", attracting much attention. Now DOING group has develo

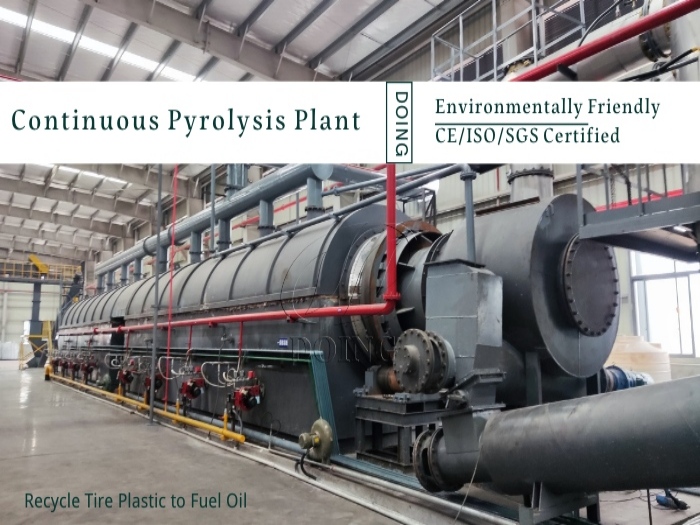

Continuous waste tyre pyrolysis plant is a kind of high efficiency pyrolysis plant developed by Doing Group on the basis of intermittent pyrolysis plant. In order to better meet the needs of customers, the continuous waste tyre pyrolysis plant adopts PLC

Pyrolysis equipment for waste plastic turned into fuel oil is a kind of environmental protection equipment which can turn waste plastics into pyrolysis oil. Pyrolysis equipment for waste plastic turned into fuel oil Waste plastic is a gener

The most significant aspect of the whole waste tire pyrolysis equipment process is simple and non-pollution.Waste tire pyrolysis equipment not only help us handle house refuse to making our living environment better but also provide precious energy ,oil.

At high temperatures and without oxygen, waste plastics undergo the above cracking process to produce plastic pyrolysis oil, carbon black and non-condensable gases. Of course, plastic pyrolysis oil is the main product obtained from plastic to oil conversi

DOING company's waste tyre recycling to oil pyrolysis plant can also handle waste plastics, waste sludge, medical waste, etc. The daily processing capacity of waste tyre recycling to oil pyrolysis plant ranges from 3-60 tons per day. Through the waste tyr

DOING company's waste plastic pyrolysis equipment is a device that converts waste plastic into fuel. It is a chemical process that breaks macromolecular plastics into smaller molecules of petroleum, natural gas and carbon black.

Leave a message

Mobile/Wechat/Whatsapp: