Home>Project Case>Six sets of 15TPD waste plastic pyrolysis plants were successfully installed in China

Six sets of 15TPD waste plastic pyrolysis plants were successfully installed in China

In June, 2023, the technical engineer team of DOING Company sent good news from the Chinese customer project site: six sets of 15TPD waste plastic pyrolysis plants in Henan Province, China were successfully installed and put into operation.

The following is the video of the operation site of the six sets of waste plastic pyrolysis plants:

The Henan DOING engineer team participated in the whole process of guiding the installation and commissioning of waste plastic pyrolysis plants. At the same time, there was a live broadcast team broadcasting the trial operation status of waste plastic pyrolysis plants, which can provide a more real understanding for our customers who have interests in our pyrolysis plants.

The following are some pictures of the installation of the waste plastic pyrolysis plants:

Pictures of the installation of the waste plastic pyrolysis plants

Pictures of the installation of the waste plastic pyrolysis plants

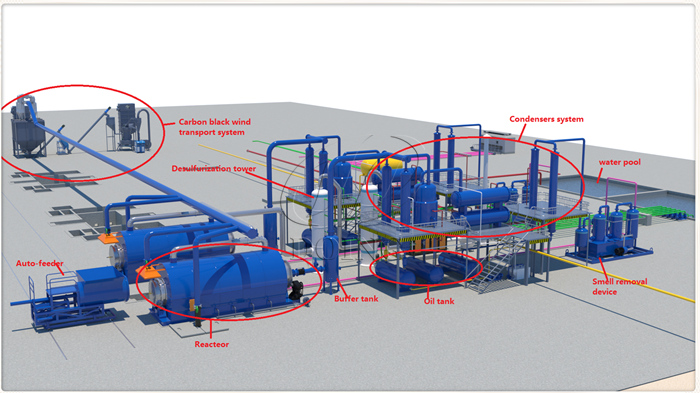

The waste plastic pyrolysis plants project has an annual processing capacity of 30,000 tons, which is in line with the national initiative on recycling waste to energy. This set of waste plastic pyrolysis plants is designed by the integration of horizontal rotary pyrolysis reactor, water tank condenser, tail-gas cleaning system, desulfurization tower, and patented negative pressure vacuum device. It has high efficiency, high output, good safety and environmental protection performance. That’s why the Chinese customer chose DOING after comparing several pyrolysis plant factories.

Detailed configurations of DOING waste plastic pyrolysis plant

Detailed configurations of DOING waste plastic pyrolysis plant

The Chinese customer is engaged in the recycling of waste plastics, so he can collect a large amount of waste plastics, including the household garbage, paper-mill waste, waste medical aluminum plastics, etc. at a cheap price, which provides a steady supply of raw materials for the customer to carry out the plastic pyrolysis machine project. After feeding and testing the six sets of 15TPD waste plastic pyrolysis plants, the customer was very satisfied with the oil output and the obtained plastic pyrolysis oil quality.

DOING pyrolysis plants and waste oil recycling machine projects

DOING pyrolysis plants and waste oil recycling machine projects

Create high-quality products with ingenuity, and create brands with high-quality products. Henan DOING Company, as an explorer in the industry of waste plastics/waste tires and other solid wastes, has extensive experience in the construction of large-scale projects such as waste tire comprehensive disposal projects and waste engine oil recycling machine projects. If you are interested in recycling waste plastics or other wastes, welcome to contact us!

Prev:DOING Brand 14TPD Waste Oil Refining Plant installed in Indonesia

Next:A set of 50 TPD fully continuous plastic pyrolysis machine successfully put into operation in Brazil

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

Leave a message

Mobile/Wechat/Whatsapp: