What happens to plastic after pyrolysis?

Plastic, a widely used material in modern society, poses a significant challenge to the environment when it becomes waste. Landfill and plastic material recovery have been widely used as the way of waste plastic management. There is a problem with landfill, as it can take up to 450 years for plastic to break down (to biodegrade), which cannot really solve the plastic pollution problem.

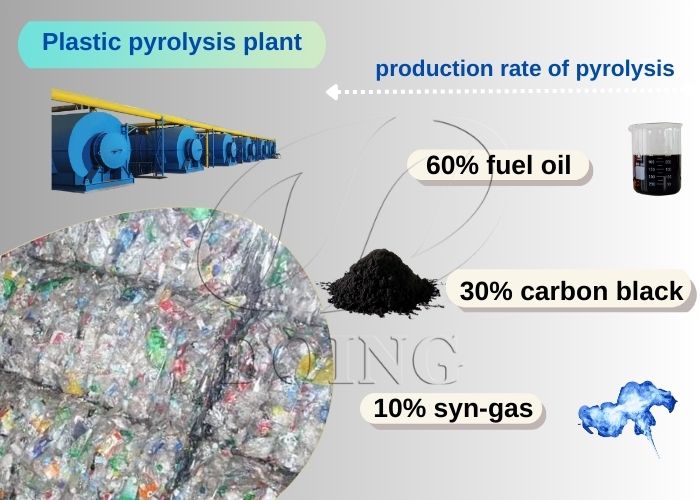

Pyrolysis is a thermal decomposition process in which large molecules are broken down into small molecules, has emerged as a promising solution to handle plastic waste. But what happens to plastic after pyrolysis?

DOING plastic to oil pyrolysis machine

DOING plastic to oil pyrolysis machine

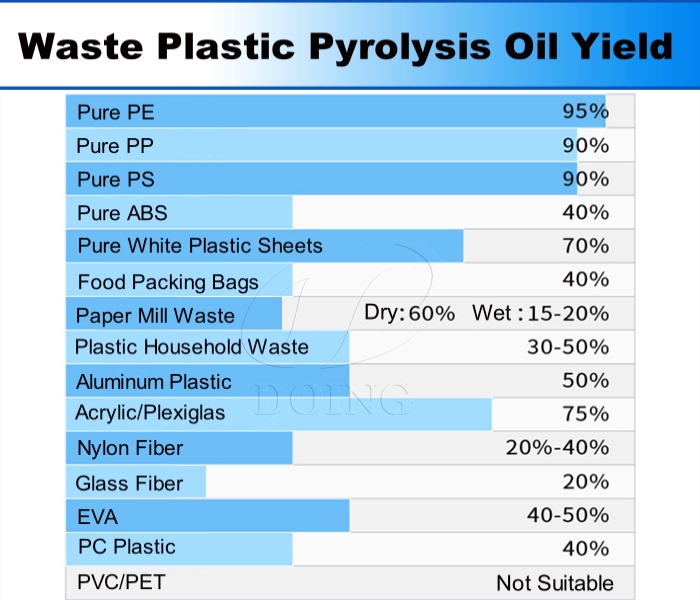

As we know, plastics are the derivatives of petroleum products and are usually made up of hydro-carbon polymers, in other words, plastic is made from crude oil obtained from the oil well. 5% of extracted oil from under the ground is used for the production of plastic materials, 90% of which form part of 5 types of plastics such as PE(polyethylene), PP(polypropylene), PVC(polyvinyl-chloride), PET(Polyethylene terephtalate ) and PS (polystyrene ). Since plastic has similar components with crude oil, so we can turn plastic back into fuel oil again through pyrolysis. In the process of plastic pyrolysis, long chain hydrocarbon polymer is broken down into smaller chains of hydrocarbon gas and pyrolysis oil.

Plastic pyrolysis oil yield

Plastic pyrolysis oil yield

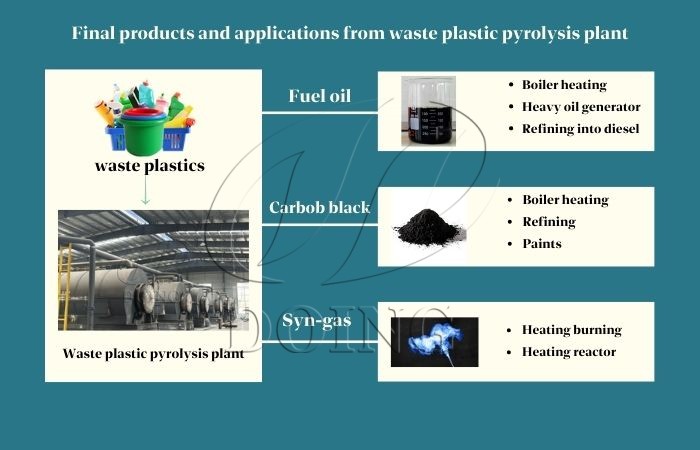

Recycling plastic into fuel oil will be a better solution to waste plastic management and it is also the one with best economical benefit. Plastic in its raw state is made up of a range of hydro-carbon polymers, after thermal pyrolysis process, the plastic polymers can be broken into smaller carbon chain which is fuel oil. This oil can be used as fuel, such as heavy oil generators, boiler heating, gypsum plants, glass plants, brick plants, steel plants, cement plants, etc. After further refinery, plastic fuel oil can be converted into plastic diesel as a diesel substitute used for industrial heating, heavy machine and generators,etc.

Another important product is carbon black. It has applications in various industries, such as the production of tires, pigments, and inks, construction. Additionally, syngas, a mixture of carbon monoxide and hydrogen, is also generated, while combustible gas can be utilized as an energy source to fuel the pyrolysis process itself, reducing the overall energy consumption.

Application of plastic pyrolysis products

Application of plastic pyrolysis products

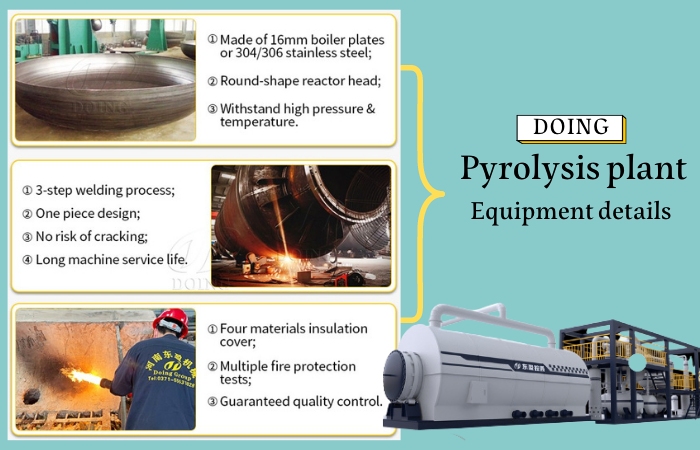

DOING waste plastic recycling pyrolysis machine is a high - quality equipment designed for this purpose. It features high efficiency, low energy consumption and environmental friendliness. The machine adopts advanced pyrolysis technology to ensure a high conversion rate of waste plastic into valuable products. It is equipped with a sophisticated gas purification system to minimize the emission of harmful gases, making the recycling process more environmentally sustainable.

In addition, DOING waste plastic recycling pyrolysis machine is easy to operate and maintain. It has a user - friendly PLC control system that allows operators to monitor and control the entire pyrolysis process with ease. The machine is also designed with safety in mind, incorporating various safety features to protect operators and ensure a smooth and trouble - free operation.

DOING waste plastic pyrolysis machine advantages

DOING waste plastic pyrolysis machine advantages

In conclusion, pyrolysis provides a promising solution for recycling waste plastics into fuel oil, carbon black and syngas. With the help of DOING waste plastic recycling pyrolysis machine, we can effectively transform waste plastic into valuable resources, contributing to a cleaner and more sustainable environment. Welcome to contact us for more details about DOING waste plastic pyrolysis machine.

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line