How to turn waste plastic into fuel?

Waste plastic is a kind of high molecular polymer, which can be treated by pyrolysis technology under suitable temperature and pressure, and then turned into low molecular weight state or monomer state, that is, fuel oil, carbon black, and combustible gas.

The fuel oil extracted from waste plastics has a wide range of uses, high value and certain economic benefits. Now let’s take Henan DOING's waste plastic pyrolysis plant as an example, let's find out the detailed waste to fuel processing process:

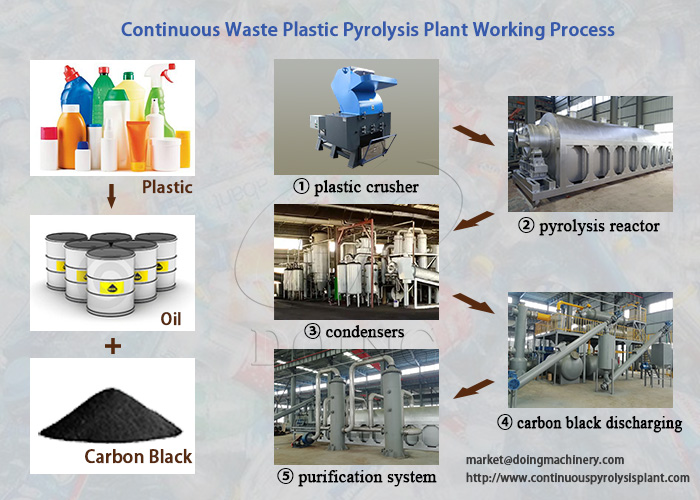

The process of waste plastics pyrolysis plant

The process of waste plastics pyrolysis plant

Step 1: Feeding----push the waste plastic into the reactor of waste plastic pyrolysis plant through automatic feeder, and close the feeding port after the feeding is completed;

Step 2: Heating----uniformly heat the pyrolysis reactor of waste plastic pyrolysis plant, and the temperature gradually rises and oil gas will be generated.

Step 3: Oil Gas cooling----then the pyrolysis oil gas will enter the cooling system and then liquefy into oil into the oil tank. The non-condensable gas will pass through the water seal and purification device, then it can be used as heating fuel for waste plastic pyrolysis reactor to save investment.

Step 4: Slag discharge----After the temperature of the pyrolysis reactor is lowered, open the slag discharge door, connect the automatic slag discharge machine to start the carbon black discharge.

According to the SGS report of plastic fuel oil samples provided by DOING's customers, the fuel oil density (15℃) extracted from waste plastics is 0.8205g/cm³, the residual carbon (trace method) is 0.14% (m/m), and the total calorific value is 0.14% (m/m). 42.86MJ/kg. This plastic fuel oil has a high calorific value and is a great heating fuel for the manufacturing industry and other industries. In addition, the fuel oil extracted from waste plastics can be further refined into non-standard bright colors through our pyrolysis oil refinery plant.

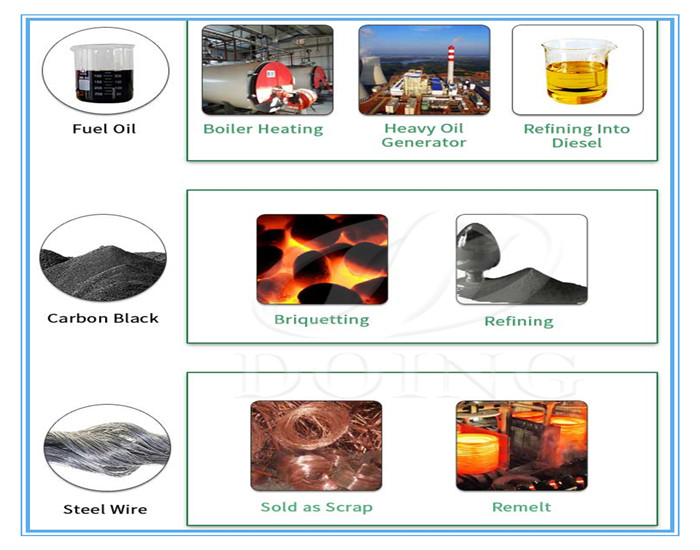

The applications of pyrolysis products

The applications of pyrolysis products

Henan Doing Company is a professional manufacturer of waste plastic to fuel pyrolysis plants, which can provide you with perfect after-sales service and technical support. The pyrolysis plant produced by DOING is widely sold in more than 100 countries and regions at home and abroad, and is deeply trusted by customers. Welcome new and regular customers to make an inquiry.

Prev:What raw material is for better output / profit of pyrolysis plant?

Next:What's the total cost of building a plastic waste to fuel pyrolysis project?

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

Leave a message

Mobile/Wechat/Whatsapp: