The Scrap Value of Tires and How to Increase Their Added Value

Scrap tires are often considered a source of environmental pollution, but they actually contain significant untapped value. With the right technologies, they can be transformed from waste into high-value resources. This article explores the inherent physical and chemical value of scrap tires, focusing on how pyrolysis technology can enhance their value, and introduces DOING scrap tire pyrolysis equipment for this transformation.

Physical Value: Recyclable Components

Scrap tires consist of three main physical components, each with recyclable potential:

1.Rubber: Accounting for 50–60% of a tire’s weight, rubber can be mechanically ground into crumb rubber for use in road paving, sports surfaces, or rubber products. However, mechanical recycling often results in low-grade rubber with limited application scope.

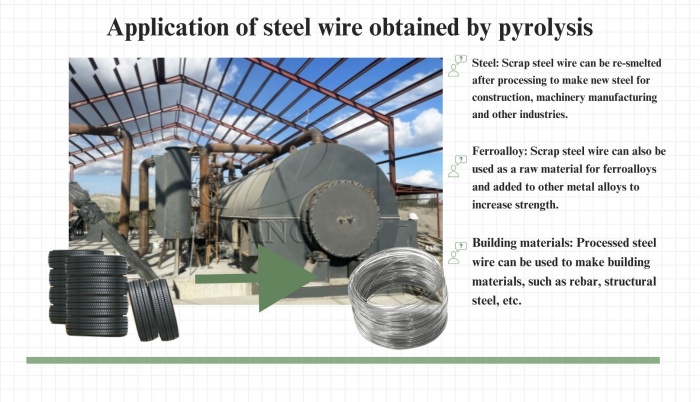

Application of steel wire

Application of steel wire

2.Steel Wire: Making up 10–15% of a tire’s weight, steel wire is a high-quality ferrous material. After separation, it can be melted and reused to produce new steel products.

3.Carbon Black: Present in 20–25% of a tire’s composition, carbon black is a reinforcing filler in rubber. While mechanical recycling can recover some carbon black, it is often contaminated and of low quality.

Chemical Value: Pyrolysis(The Key to Maximizing Scrap Tire Added Value)

Pyrolysis, the process of decomposing organic materials at high temperatures in the absence of oxygen. Tires are made of synthetic rubber, natural rubber, and other organic compounds, which are rich in hydrocarbons. Unlike mechanical recycling (which only recovers rubber and steel wire) or incineration (which wastes most resources), pyrolysis converts scrap tires into four high-value products:

1. Pyrolysis Oil: A liquid fuel, accounting for 40-45% of total production, with a calorific value of 42-45 MJ/kg (comparable to diesel). It can be used directly in industrial burners or further refined into diesel for heavy machinery or diesel generators, making it an ideal alternative to traditional fossil fuels.

Application of pyrolysis oil

Application of pyrolysis oil

2. Recovered Carbon Black (rCB): A solid residue, accounting for 30-35% of total production. Pyrolysis carbon black has higher purity than mechanically recycled carbon black and can be used in rubber production, ink manufacturing, or as a fuel additive. rCB can replace virgin carbon black, reducing reliance on petroleum-based production and offering a more sustainable alternative.

3. Steel Wire: Steel wire, accounting for 15% of total production, which is recovered in its original form (95% purity) can be sold to the scrap metal recycling industry at a higher price than mechanically separated steel wire.

4. Syngas: Accounting for 6-8% of total total production, the combustible and non-condensable exhaust gas can be used as fuel to heat the pyrolysis reactor.

Based on the above introduction to physical and chemical pyrolysis recycling methods for tires, we can make a simple comparison of the recycling value of scrap tires:

| Recycling methods | Raw material | Price |

| Direct sale | Scrap tires | 200$-300$ |

| Crushing | Rubber powder | 200$-500$ |

| Pyrolysis | Pyrolysis oil | 700$-900$ |

| Carbon black | 60$-90$ | |

| Steel wire | 30$-50$ |

As a result, tire pyrolysis offers higher added value. To realize the high-value uses above, a reliable pyrolysis machine is essential. DOING scrap tire pyrolysis machine is designed to maximize scrap tire value:

1.Complete Supporting Equipment: DOING pyrolysis production lines offer a variety of feeding systems, pyrolysis reactors, condensers, carbon black collection devices, and carbon black recovery devices for your selection, ensuring the best solution within your budget.

2.High Efficiency and Stable Operation: DOING pyrolysis machines utilize horizontal reactors, ensuring uniform heating (350–550℃) and are equipped with a PLC intelligent control system. This ensures complete pyrolysis of scrap tires, achieving an oil yield of 42–45%, higher than the industry average of 38–40%. The reactors are made of national standard materials, and stainless steel can also be customized, extending their service life to 6–8 years.

3.Environmentally Friendly: Multi-stage waste gas treatment (tail gas treatment device + flue gas treatment device) complies with global environmental standards, resulting in zero pollution.

DOING continuous tire pyrolysis machine

DOING continuous tire pyrolysis machine

By investing in advanced pyrolysis equipment, we can shift the paradigm. Instead of treating tires as low-value scrap, we can process them into strategic resources, creating a circular economy that turns an environmental burden into a source of significant economic and ecological added value. Welcome to contact DOING for advanced pyrolysis equipment.

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line