What are the factors that affect the oil yield of tire pyrolysis?

With the development of pyrolysis technology, now our customers can use waste tires as material to get fuel oil by pyrolysis plant. This is a kind of very good heating fuel, with 10592.48Kcal/kg heating value, which is much higher than that of coal. It has a good market in different countries. So people want to get more oil out of their tires. Then what are the factors that affect the oil yield of tire pyrolysis?

Get oil from waste tires

Get oil from waste tires

This problem can not be unified, it is mainly affected by the following several factors.

1. Type of waste tires

We have sold pyrolysis plant for many years, and through customer feedback, we get more accurate data.

About 45% fuel oil from big car tires .

About 40% fuel oil from small car tires and bicycle tires.

About 35% fuel oil from rubber cable skin or sole, about 30% fuel oil from mixed sole. More than 30% fuel oil from waste chemical fiber carpet material.

About 35% of fuel oil from Miscellaneous rubber.

In short, Different types of tires lead to different oil yields from 30% to 45% after pyrolysis, which means you can get 300kg-450kg fuel oil from 1ton waste tires pyrolysis plant.

Different types of tires

Different types of tires

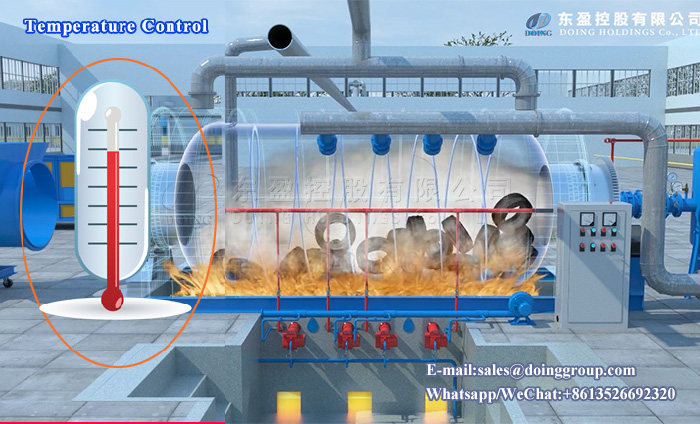

2. Temperature control

The highest oil yield temperature is between 280 ℃ and 300 ℃. If the temperature can be well controlled during the pyrolysis process, the oil production rate will also be improved.

Temperature control during pyrolysis

Temperature control during pyrolysis

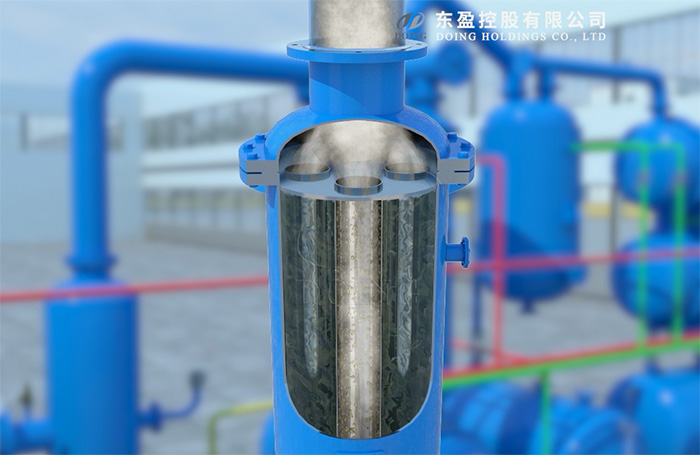

3. Condensing equipment

We all think that the more condensers there are, the better the effect will be. Not quite. Sometimes the process of the equipment is also very important. DOING adopt the way of tube condensation, 4 processes and 7 condensers can ensure that the oil gas are fully condensed, and the whole equipment can reach 70 square meters.

DOING tube condensation

DOING tube condensation

Therefore, when you do a tire pyrolysis oil project, you need to combine the above factors to increase the oil production rate and increase the profit.

Prev:How do you make oil from waste tires?

Next:How to choose a professional waste platic pyrolysis plant manufacturer?

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

Leave a message

Mobile/Wechat/Whatsapp: