Home>News>Industry News>Brazil customer ordered a set of 15T/D batch waste tire pyrolysis plant from Doing Group

Brazil customer ordered a set of 15T/D batch waste tire pyrolysis plant from Doing Group

On 18th,May, Doing Group got a new order from Brazil. The Brazil customer ordered a set of 15T/D batch waste tire pyrolysis plant. This is the second time that Brazilian customers have bought equipment from DOING Factory since May this year.

Waste tire pyrolysis plant

Waste tire pyrolysis plant

When purchasing the batch waste tire pyrolysis plant, the Brazil customer was more concerned about environmental issues and hoped to find a set of batch waste tire pyrolysis plant in line with local environmental protection requirements. Our project manager introduced to the customer the new generation of environment-friendly waste tire pyrolysis plant produced by Doing Group and the measures taken by Doing Group in the environmental protection system to meet the environmental protection requirements.

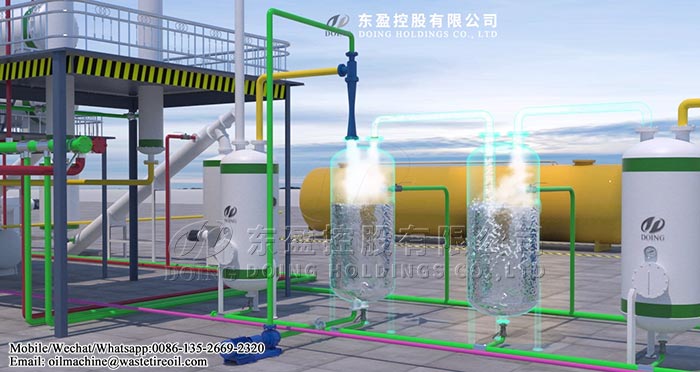

The tail gas cleaning system

The tail gas cleaning system

The environmental protection system of the waste tire pyrolysis plant includes tail gas cleaning system and smoke cleaning system. The tail gas cleaning system can remove 80-90% harmful emissions, like H2S, Sulfides and Nitrogen Oxides, etc,thus to meet the emissions standard. In addition to the tail gas cleaning system, the smoke cleaning system can effectively purify the smoke produced in the process of fuel combustion, which could be discharged without causing secondary pollution to the environment.

The smoke cleaning system

The smoke cleaning system

The waste tire pyrolysis plant produced by Doing Group has passed the European and American environmental standards, and there are many project cases in more than 40 countries around the world. If you are interested in environment-friendly waste tire pyrolysis plants, please contact us, our engineers will provide suitable solutions for you. Welcome to consult.

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

- What are the types of materials pyrolysis equipment can process?

- How can we turn plastic waste into green energy?

- Does it need to add catalysts in the tire plastic pyrolysis process?

Leave a message

Mobile/Wechat/Whatsapp: