Indonesian customer purchased 2 sets of 10T waste tire pyrolysis plants

On September 20, 2023, our Indonesian customer purchased 2 sets of 10T waste tire pyrolysis plants from Henan Doing Company. He purchased these two sets of pyrolysis plants to recycle cheap waste tires into valuable fuel oil energy.

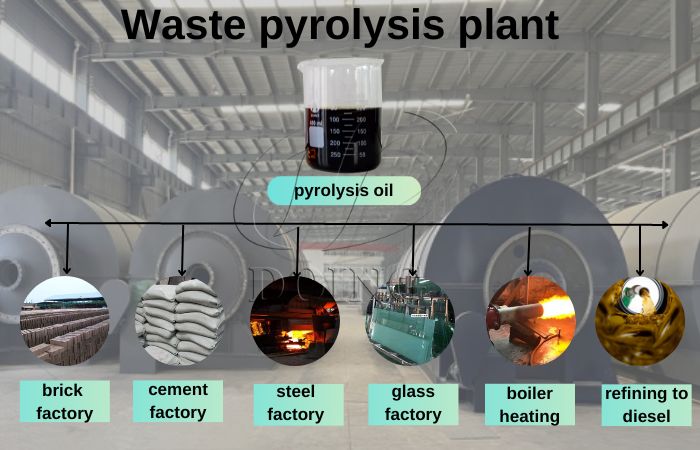

Our Indonesian customer has a big factory in Indonesia, and to save heating fuel costs, he decided to produce alternative fuel-heating fuel by himself. For excess fuel beyond demand, he can sell it to other factories, like heavy oil power plants, steel factories, glass factories, cement factories, boiler heating, etc. In Indonesia, where oil prices remain high, this is a lucrative business.

Waste tire pyrolysis plant final product application

Waste tire pyrolysis plant final product application

After doing market research, our Indonesian customer decided to use the cheap and available waste tires as the raw materials. Then he looked for professional pyrolysis plant manufacturers to customize suitable waste tire pyrolysis plant purchasing schemes.

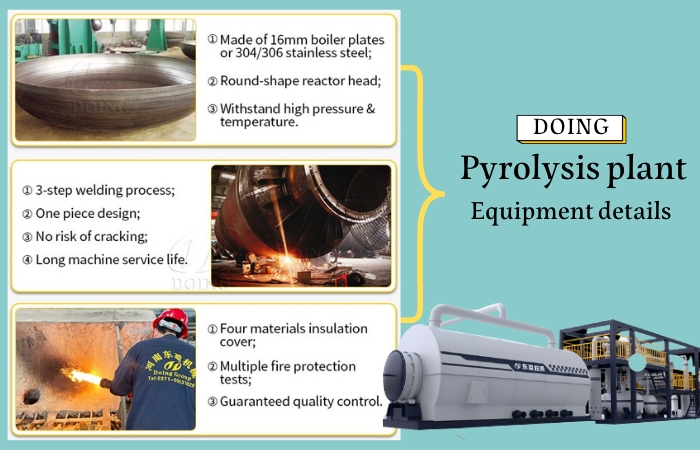

DOING Company has rich pyrolysis plant exportation and installation experience. Our prolysis plant has been popular sale to 100+ countries and regions, including Indonesia. Besides that, no matter in machine quality and machine environment protection design, our waste tire pyrolysis plants have great performance. Therefore, from machine selection to installation, we can offer all-around services to help our customers install the waste tire pyrolysis plants smoothly. That's why our waste tire pyrolysis plant stands and became the preferential choice of our Indonesian customer.

Waste tire pyrolysis plant final product application

Waste tire pyrolysis plant final product application

If you are interested in setting up waste tire/plastic/oil sludge recycling pyrolysis plants to produce fuel oil, please feel free to send us your inquiry. Our sales manager and engineer team can customize a suitable pyrolysis plant solution and introduce the machine details to you!

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

Leave a message

Mobile/Wechat/Whatsapp: