What is the feature of DOING continuous plastic pyrolysis plant?

Nearly years, many customers have invested in plastic pyrolysis plants to dispose of waste plastics and make profits from it. As the market matures, customers have put forward higher requirements for efficiency and environmental protection, so DOING continuous plastic pyrolysis plant has been well received. Then we're going to talk about the feature of DOING continuous plastic pyrolysis plant and this is the reason why DOING continuous plastic pyrolysis plant are so popular at home and abroad.

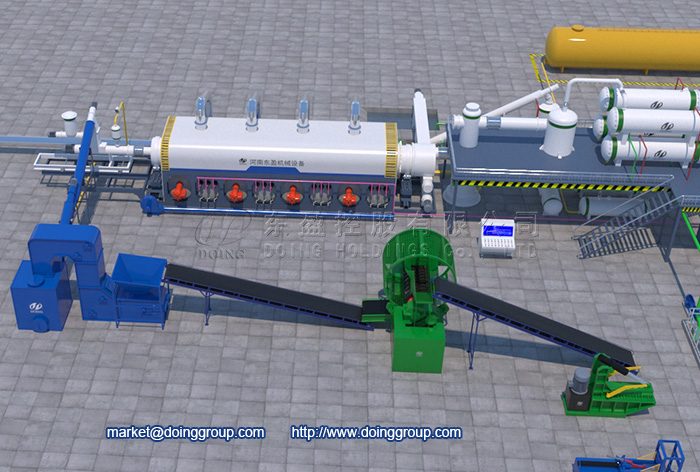

DOING continuous plastic pyrolysis plant

DOING continuous plastic pyrolysis plant

In general, DOING plastic pyrolysis plan can be divided into batch and continuous categories. Plastic batch type and continuous plastic pyrolysis plant work on the same principle, but continuous plastic pyrolysis plant have been further improvements in automation and environmental protection. Here are its features.

→ Stabilization

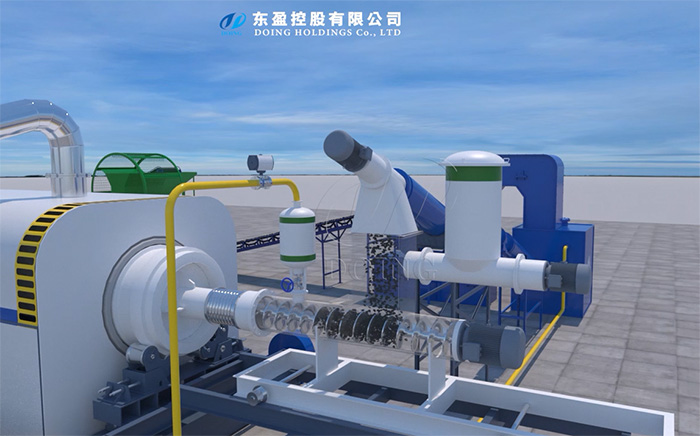

A: The pyrolysis reactor adopts automatic welding, which can not only greatly improve work efficiency but also ensure the quality of welding seam, so as to avoid explosion caused by oil gas leakage.

B: Special X-ray flaw detection technology to further ensure the perfect weld.

C: Negative pressure equipment can prevent oil gas flow back, avoiding risks.

D: Thermometers, manometers, stabilization valves and other adequate stabilization devices.

→ Environmental protection

A: Special water film dust removal system can make the tail gas reach international environmental standards.

B: The recycling tail gas can be used for heating reactor, so no gas pollution, and can save fuel.

C: The pyrolysis reactor is sealed with special sealing materials to avoid accidents.

Sealed continuous plastic pyrolysis plant

Sealed continuous plastic pyrolysis plant

→ Long service life

A: The reactor material: Q245R special steel plate, thickness of 16mm.

B: Welding: automatic welding weld, X-ray flaw detection technology detection, maximum extend the service life of the reactor for around 8--10 years.

Pyrolysis reactor

Pyrolysis reactor

→ Energy saving

A: The system is well sealed, and no gas leakage, which can also save fuel.

B: The exhaust gas is recycled to heat reactor which can save fuel and cost.

The feature of continuous plastic pyrolysis plant we have talked about above are the reasons why it is widely favored by domestic and foreign customers. In the future, this project is still considerable. If you like this project, please contact with us immediately.

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line