What is the difference between batch and continuous pyrolysis plant?

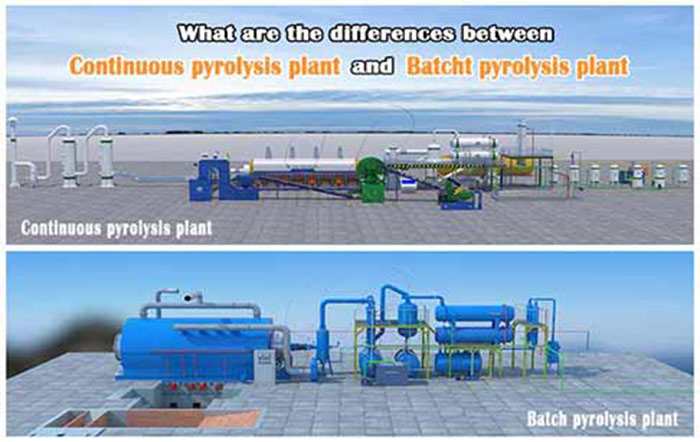

According to the different processes, the waste plastic pyrolsis plant can be divided into two types: batch waste plastic pyrolysis plant and continuous waste plastic pyrolysis plant. Customers who want to buy waste plastic pyrolysis plants often ask: What is the difference between continuous waste plastic pyrolysis plant and batch waste plastic pyrolysis plant? Here I will tell you the difference between the two equipment.

Waste plastic pyrolysis plant

Waste plastic pyrolysis plant

1.The workshop environment is different.

The continuous waste plastic pyrolysis plant operation process is fully enclosed, the carbon black is centrally packaged, no dust is discharged, and the workshop environment is excellent.

Batch waste plastic pyrolysis plant needs to open the furnace door, some dust will enter the air, and the workshop environment is poor.

The batch waste plastic pyrolysis plant

The batch waste plastic pyrolysis plant

2. There fuel consumption is difference.

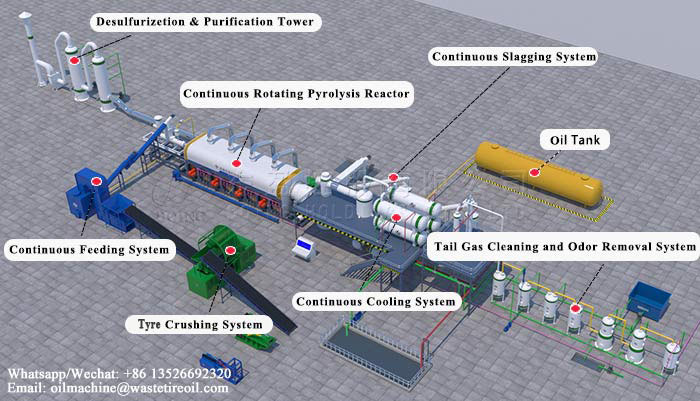

The continuous waste plastic pyrolysis plant adopts an automatic fully enclosed continuous feeding and slagging system, which allows re-feeding or slagging at a high temperature of more than 200 degrees, thus greatly saving time and fuel costs between two furnaces, and operating costs can be saved by 20%. In addition, The combustible gas produced by pyrolysis can be used 100%, saving 70% of fuel.

Batch waste plastic pyrolysis plant needs to meet the needs of secondary feeding or slag discharge or wire drawing. The temperature of the pyrolysis reactor needs to be cooled to below 60 degrees. In addition, due to intermittent production, combustible gas cannot be continuously produced, so the pyrolysis plant needs additional fuel consumption, and the combustible gas produced by pyrolysis cannot be fully recycled.

The continuous waste plastic pyrolysis plant

The continuous waste plastic pyrolysis plant

3. The daily processing capacity is different.

The continuous waste plastic pyrolysis plant has a daily processing capacity of 16-20 tons with high work efficiency.

The daily processing capacity of batch waste plastic pyrolysis plant is 8-10 tons, and the work efficiency is relatively low.

Waste plastic pyrolysis plant

Waste plastic pyrolysis plant

The above is the difference between the two types of equipment. Both batch waste tire pyrolysis plant and continuous waste tire pyrolysis plant have their own characteristics.Doing Group suggests that customers should consider comprehensively when purchasing, and purchase waste tire pyrolysis plant that suits their own production needs. If you want to know more information about waste tire pyrolysis plants, welcome to consult us.

Prev:How to choose waste plastic pyrolysis plant?

Next:How long is the payback period of investing waste plastic pyrolysis plant project?

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line