Used engine oil refining into diesel oil equipment

With the increase of motor vehicles, the number of waste engine oil is increating year by year, and waste oil can cause great pollution to the environment. Therefore, we need to find a suitable way to dispose of waste oil. The best way is to recycle waste oil and turn it into diesel. Next, let's take a look what kind of machine can refine waste oil into diesel.

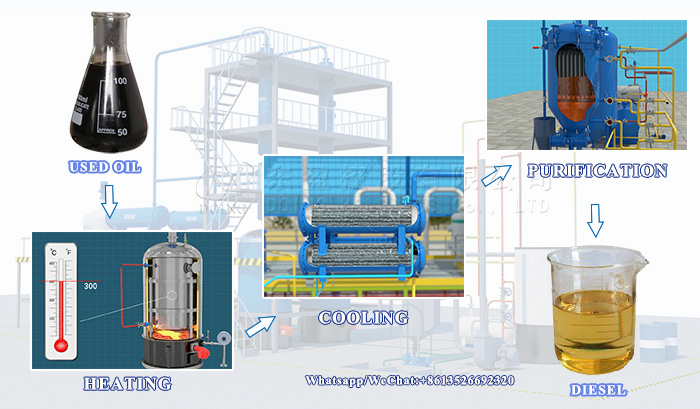

Doing Group waste oil distillation machine can refine waste oil,such as tire pyrolysis oil, plastic pyrolysis oil, waste engine oil, black and heavy oil, curde oil, etc. into light diesel, the final diesel product could be used as alternative fuel in diesel burnes,enerators,heavy machinery and agricultural machiery,etc. The whole process includes high temperature distillation, circulation water cooling,catalyst deodorization and clay decolorization. Next, let's see the detailed workflow of waste oil distillation machine.

Waste oil distillation machine

Waste oil distillation machine

The main working flow of Doing Group waste oil distillation machine is as follows:

1. Pour the heat transfer oil into the heat transfer system, the heat conduction oil is mainly to preheat the system.

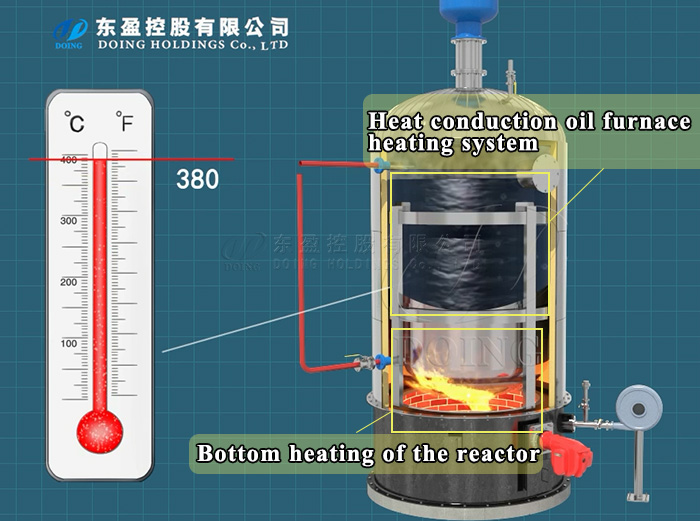

2. When the temperature of the distillation reactor reach 290 degrees, turn on the burner to heat distillation reactor, and control the temperature of the distillation reactor between 380 degrees and 400 degrees, and the oil gas will generate;

3. The oil gas will be cooled downed into light fuel oil through the cooling system and flow into the oil tank.

4. Then, the light fuel oil can be purified through catalyst deodorization and clay decolorization to obtain diesel.

Workflow of waste oil distillation machine

Workflow of waste oil distillation machine

Compared with equipment from other manufacturers, our waste oil distillation machine has the following advantages:

1. The reactor adopts a vertical design, which is easier to discharge than a horizontal design.

2. Double heating system, that is, heat-conducting oil circulating heating and direct fuel heating. Compared with the single heating system, the double heating system can achieve rapid heating, shorten the heating time, improve the equipment operating efficiency.

3. The number of reactors can be added according to the user's throughput. The capacity of each reactor is 5 tons. If you need to handle 10 tons, you can add a reactor and so on.

4. The purification system of waste oil distillation machine can deeply purify refined diesel to obtain bright-colored and high-quality diesel products.

The double heating system

The double heating system

After many successful cases, it has been proved that waste oil distillation machine has a very broad market. This is because Doing Group waste oil distillation machine can obtain non-standard diesel(80-80%) and asphalt(10-15%). In particular, non-standard diesel has a very important role in our lives. Of course, this is also the main source of profit for this equipment.

The application of diesel and asphalt.

1. The diesel can be used in diesel combustion engines, generators, heavy machinery and agricultural machinery instead of standard diesel. Because the diesel is non-standard, which cannot be used directly on cars. If you want to use it on cars, you need to mix it with standard diesel.

2. The asphalt can be used for paving or sold directly to an asphalt refinery for further refining.

Diesel oil application

Diesel oil application

The above is the introduction to the waste oil distillation machine, besides, we also provides 3D animation video of waste oil distillation machine to helo customers know more information. If you have other questions, welcome to consult us, our engineers will provide suitable solutions for you.

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

Leave a message

Mobile/Wechat/Whatsapp: