How long is the payback period of investing waste plastic pyrolysis plant project?

Most customers calculate their ROI before starting a pyrolysis project, and then they consider how long it will take to return their investment.We all know that the first thing to consider when opening a waste plastic pyrolysis project is machinery cost, then the site cost, labor cost and other costs. In addition to these costs, there are some cost factors that may not considered by customers . Next, I will give you an analysis.

The waste plastic pyrolysis plant

The waste plastic pyrolysis plant

1.Raw material costs

The method of obtaining raw materials is generally divided into two aspects: On the one hand, some countries may choose to landfill waste plastics directly. But the degradation rate of plastic is very slow and plastic can be broken down into toxic chemicals that pollute land and sea and destroy wildlife habitats.So when customers want to recycle plastic to pyrolysis oil, they can get municipal or government support, and the raw material is generally not too costly or even free. On the other hand, if you need to buy raw materials, you can calculate the raw material cost according to the plastic price on the market.

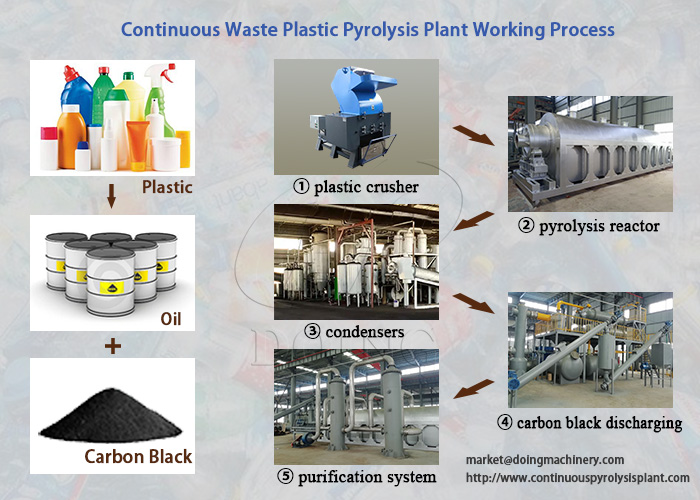

Continuous waste plastic pyrolysis plant working process

Continuous waste plastic pyrolysis plant working process

2.The price of fuel oil

The mainly end product of waste plastic pyrolysis is fuel oil, so customers can get great profit from fuel oil. From the point of view of the market, fuel oil demand is tight and the price of fuel oil is relatively high. Boiler factories, glass factories, brick factories and other industries can not be separated from fuel oil as heating fuel. Therefore, the market fuel price is relatively optimistic and there is a lot of room for development. In addition, we have received feedback from our Indian customers recently that the price of fuel oil has even doubled, which means your profit period can be greatly accelerated.

The pyrolysis oil application

The pyrolysis oil application

Above all, there are many factors can affect your profit period. If you want to know the specific price of waste plastic pyrolysis plant and further calculate how long it will take you to make a profit, please contact us feel free.

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

Leave a message

Mobile/Wechat/Whatsapp: