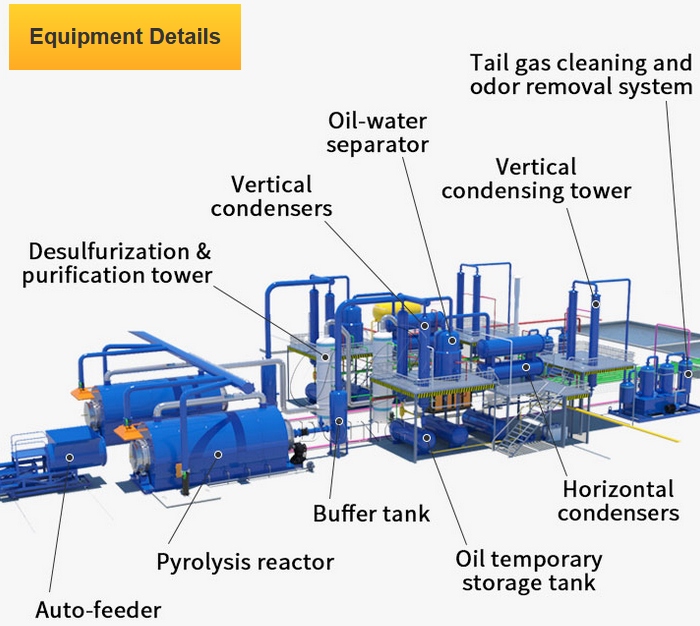

Equipment composition of waste plastic oil pyrolysis production line

The waste plastic oil pyrolysis production line adopts a well-designed set of process principles, which is composed of a series of equipment with different functions. It can be mainly divided into waste plastic pretreatment equipment, waste plastic oil pyrolysis condensation equipment, various environmental protection and optional equipment, etc. Each equipment structure works together so that waste plastics can be converted into fuel oil, carbon black and combustible gas under the premise of safety and environmental protection.

Waste plastic oil pyrolysis production line equipment components

Waste plastic oil pyrolysis production line equipment components

The following is a brief introduction to the equipment composition of the entire waste plastic oil pyrolysis equipment production line:

Waste plastic pretreatment section

1. Waste plastic sorting equipment

There are many types of waste plastic raw materials, and some hard solids such as metals and stones are easily mixed in the collection process. If the waste plastic you want to process has a large amount of impurities, it is best to sort the plastic. DOING waste plastic oil pyrolysis production line includes auxiliary sorting equipment such as magnetic separators, electric separators, and plastic balers, etc. Customers can choose according to their needs.

2. Waste plastic crushing equipment

If DOING batch waste plastic oil pyrolysis production line is used, there is no strict feeding requirement for waste plastic raw materials. The waste plastic or packaged waste plastic can be directly put into the reactor. If a semi-continuous or fully automatic continuous waste plastic oil pyrolysis production line is used, the waste plastic needs to be crushed into small pieces of 30-50mm before being put into the reactor.

Waste plastic pretreatment machine

Waste plastic pretreatment machine

3. Waste plastic dehydration equipment

If the waste plastic has a large water content, such as plastic scraps from paper mills, directly putting it into the reactor may cause the quality of the plastic pyrolysis oil to deteriorate and the amount of oily wastewater to increase. Then it is necessary to use a drying cylinder to dehydrate the waste plastic to ensure the stable operation. It should be noted that the drying temperature should not be too high, because some waste plastics are not resistant to high temperatures, which may cause premature oil production and cause some losses.

Waste plastic oil pyrolysis condensation section

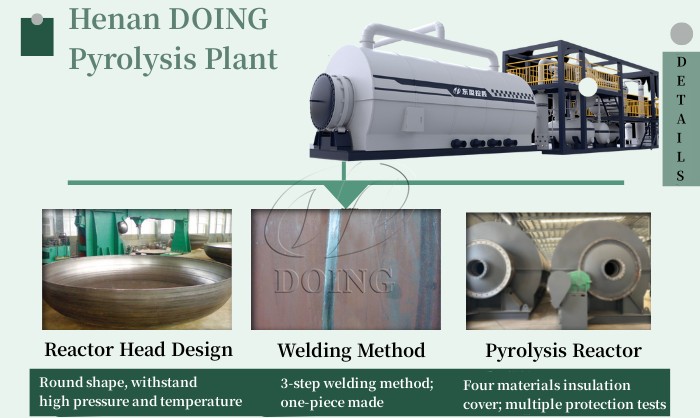

1. Pyrolysis reactor

The equipment that heats waste plastics to a certain temperature and vaporizes them into liquid oil is called a pyrolysis reactor. Henan Doing Company supplies batch, semi-continuous, and fully automatic continuous waste plastic oil pyrolysis production lines. The capacity and process of the pyrolysis reactor used in each type of equipment will be different. At the same time, DOING also provides a variety of pyrolysis reactor manufacturing materials, such as Q345R, Q245R, 304 stainless steel, 316 stainless steel, etc. Customers can choose according to the characteristics of the raw materials.

Waste plastic oil pyrolysis reactor

Waste plastic oil pyrolysis reactor

2. Condensation equipment

Condensation equipment can also be called heat exchange equipment or plastic oil cooling system, that is, by transferring heat from high-temperature fluid to low-temperature fluid to achieve the effect of cooling oil and gas and liquefying it into oil. Nowadays, the common condensing equipment on the market can be divided into water tank condensing equipment and shell-and-tube condensing equipment according to the device.

Various optional sections

1. Waxing device

Common waste plastic pyrolysis raw materials generally include PP, PE, PS, ABS, aluminum plastic, food packaging bags, paper mill scraps, plastic mulch, etc. Among them, PE plastic has a relatively high oil yield, but it is easy to wax. In order to improve the overall working performance of waste plastic oil pyrolysis production line and shorten the cleaning time of the equipment, it is best to configure the waxing device, which can effectively prevent the problem of waxing blockage and improve the operation efficiency of the equipment.

2. Environmental protection device

If you want to make a regular waste plastic low-temperature pyrolysis production line and obtain environmental assessment qualifications, you need to install matching environmental protection devices. Henan Doing can provide exhaust gas purification devices, waste gas desulfurization and denitrification equipment, dust removal devices, activated carbon adsorption devices, etc., which can be configured according to the policy requirements of your local government.

Environmental devices of plastic oil pyrolysis production line

Environmental devices of plastic oil pyrolysis production line

3. Safety devices

The overall safety properties of waste plastic oil pyrolysis production line need to be implemented from the beginning of process design, equipment device materials, welding and manufacturing. In order to further improve the safety of the equipment during operation, DOING waste plastic oil pyrolysis production line is equipped with buffer tanks (slowing down the oil gas flow rate), water seals (preventing exhaust gas backflow), vacuum negative pressure devices (preventing flash explosions) and other safety equipment, as well as flow gas detection, pressure gauges, temperature gauges, alarm bells and other safety accessories, etc.

Storage structure section

The oil products and carbon black produced after the pyrolysis of waste plastics need to be collected through storage equipment. Generally, there are vertical storage tanks, horizontal storage tanks and bags according to the structure, which can be selected and designed according to the daily processing volume, equipment structure, and plant size.

Waste plastic oil pyrolysis production line

Waste plastic oil pyrolysis production line

It is these important equipment structures that constitute a complete waste plastic oil pyrolysis production line. Because the framework of the waste plastic oil pyrolysis production line is relatively complex, there are various pipeline designs, automation designs, and feeding methods that need to be discussed and customized. If you want to know more, you can communicate with the Henan Doing’s technical team to get a waste plastic pyrolysis production line design that better matches your personal needs.

Prev:How to Improve the Quality of Plastic Pyrolysis Oil?

Next:What are the types of materials pyrolysis equipment can process?

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

Leave a message

Mobile/Wechat/Whatsapp: