DOING Jordan 15 Tons Batch Plastic Pyrolysis Equipment Installed

In June 2025, DOING Company accomplished the setup of a plastic pyrolysis equipment in Jordan. The installed equipment is a 15-ton batch plastic pyrolysis equipment, primarily processing paper mill waste.

DOING 15TPD plastic pyrolysis machine installed in Jordan

Customer Profile

The Jordan customer mainly operates a paper mill. A large amount of waste like paper mill rejects occurs during paper production, presenting storage and environmental issues. To address these and transform waste into resources, the customer explored plastic pyrolysis technology. As a newcomer to plastic pyrolysis, the customer even hired professional evaluators to pick suppliers. After assessing pyrolysis tech types, manufacturer strengths, and services, DOING was chosen.

Waste plastic pyrolysis technology

Corporate Strength

As a pyrolysis equipment supplier with over 14 years of experience, DOING has successfully executed multiple plastic pyrolysis projects for paper mills in China, Indonesia, Taiwan, etc. The customer visited DOING's factory to gauge its capabilities. DOING demonstrated its extensive experience and R & D prowess in pyrolysis equipment manufacturing, impressing the customer with its professionalism and comprehensive solutions, leading to a finalized deal.

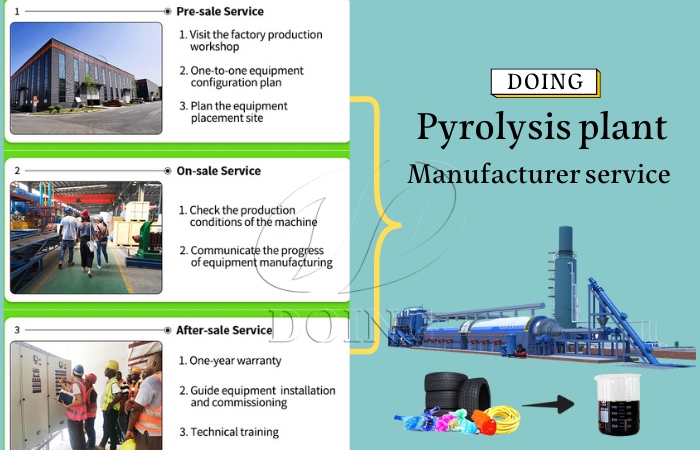

DOING pyrolysis equipment manufacturer services

Equipment Details

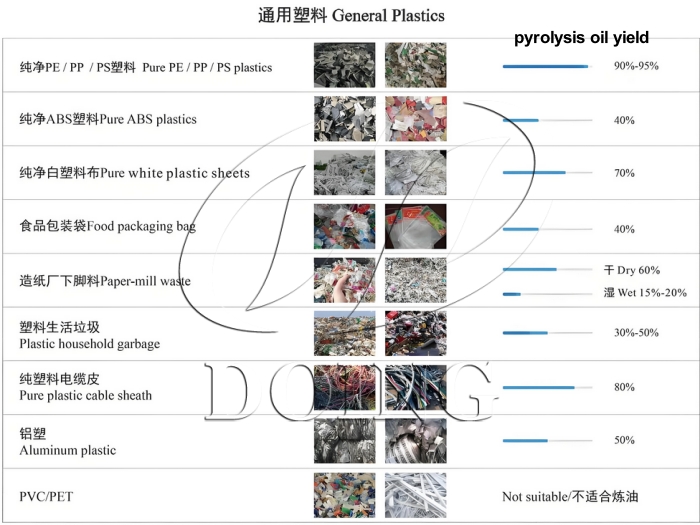

The installed 15-ton batch plastic pyrolysis equipment in Jordan is one of DOING's popular pyrolysis products. It's designed for efficient and eco - friendly processing of plastic waste such as PE, PP, PS, ABS, white plastic, and plastic cable sheaths. Using advanced pyrolysis tech, it converts plastic waste into valuable pyrolysis oil, which can be further refined for various uses. With a high - efficiency heating system and precise temperature control, it ensures stable pyrolysis reactions. The equipment also has multiple safety features like automatic pressure release devices and leak detection systems for safe operation.

Plastic pyrolysis equipment raw materials

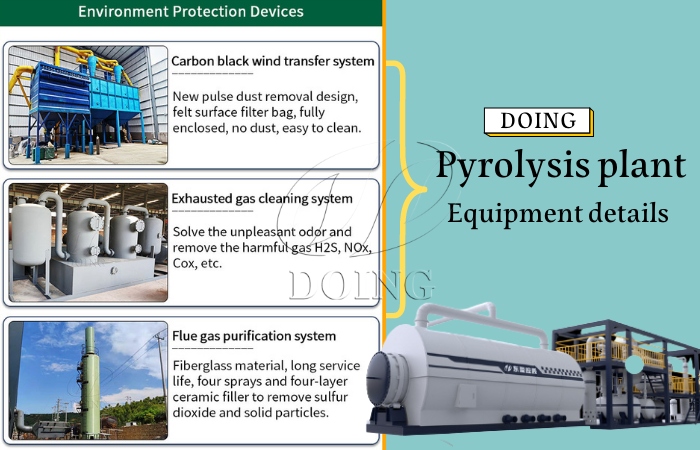

DOING pyrolysis equipment environment protection devices

The successful establishment of this plastic pyrolysis project in Jordan once more highlights DOING's strong project implementation capabilities. As a leading pyrolysis equipment company, DOING has earned global customer trust with its large - scale production and outstanding strength. Committed to providing high - quality and efficient pyrolysis equipments, DOING anticipates more global collaborations.

Prev:Nothing

Next:Fiji Waste tire plastic to diesel pyrolysis distillation machines installation project

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

Leave a message

Mobile/Wechat/Whatsapp: