Is pyrolysis better than incineration?

The question of whether pyrolysis is better than incineration cannot be answered with a simple "yes" or "no." The two waste treatment technologies have their own characteristics and applicable scenarios. However, pyrolysis does demonstrate superior performance in certain aspects compared to incineration. Below is a detailed comparison and analysis of the two technologies.

Comparison of pyrolysis and incineration

Environmental Performance: Pyrolysis Significantly Reduces Pollutant Emissions

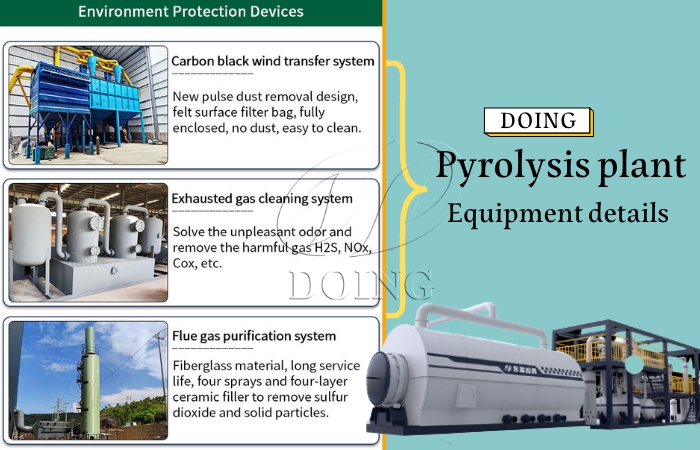

Pyrolysis is a thermal treatment technology carried out in an oxygen-free or anoxic environment. During the process, harmful gases such as SO₂, NOₓ, and HCl are significantly reduced. Additionally, harmful elements such as sulfur and heavy metals are largely fixed in the carbon black, effectively reducing the risk of secondary pollution.

DOING pyrolysis plant environment protection devices

In contrast, incineration involves high-temperature oxidation reactions. While it can achieve certain pollutant reductions, the combustion process may generate significant amounts of harmful gases such as sulfur oxides, nitrogen oxides, and dioxins. Even with advanced flue gas treatment systems, the overall pollutant emissions from incineration are still higher than those from pyrolysis.

Resource Recovery Efficiency: Pyrolysis Enables Waste-to-Resource Utilization

Pyrolysis technology can convert organic waste into valuable resources, such as syngas, fuel oil, and carbon black. For example, when pyrolysis is applied to waste plastics, scrap rubber, old tyres, biomass waste, hazardous oil sludge waste, and other organic materials, the resulting fuel oil can be used as heating fuel in steel mills, cement plants, boilers and heavy oil power plant. Furthermore, the fuel oil can be further refined by pyrolysis oil refinery plant for a wider range of uses. While the carbon black can be used in tire and rubber production, as well as as a construction material. This not only reduces waste but also achieves resource recovery.

Final products and applications from waste pyrolysis plant

While incineration can recover heat energy, the resources produced are relatively limited. Primarily, it generates electricity or heat, which has relatively low added value. Moreover, the ash and slag generated during incineration may contain harmful substances and require further treatment, increasing the complexity of the entire waste management process.

Treatment Object Flexibility: Pyrolysis Excels in Treating High-Organic Waste

Pyrolysis technology is particularly suitable for treating high-organic waste such as plastics and rubber. Under pyrolysis conditions, organic matter can be effectively decomposed into smaller molecules, generating liquid oil, combustible gas, and solid residues. This process enables both waste reduction and resource recovery.

Raw mateials of pyrolysis

Incineration, on the other hand, is more suitable for treating waste with high moisture content, such as food waste and municipal solid waste. The high-temperature combustion reaction can rapidly reduce waste volume and weight (to 5%–20% of the original size). However, for high-organic waste like plastics and rubber, incineration may face challenges such as incomplete combustion and secondary pollution.

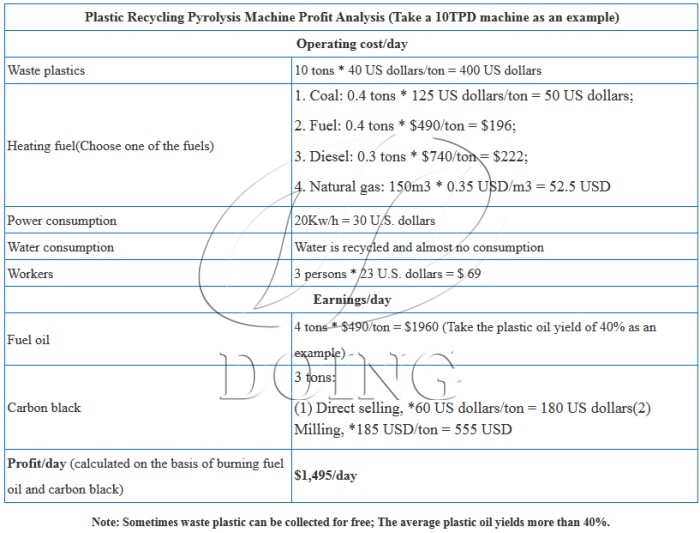

Economic Viability: Pyrolysis May Provide Greater Long-Term Benefits

From an economic perspective, pyrolysis technology offers certain advantages. First, resource recovery (e.g., fuel oil and carbon black) can generate revenue, offsetting part of the operational costs. Second, the relatively low pollutant emissions reduce the costs of environmental governance and compliance.

Plastic pyrolysis machine profit analysis

While incineration can recover heat energy for power generation or heating, the high initial investment and operational costs (e.g., flue gas treatment systems) may offset some of its economic benefits. Additionally, the maintenance costs of incineration facilities are typically higher than those of pyrolysis equipment.

Applicable Scenarios: Pyrolysis Is Better Suited for Certain Waste Types

Based on the above analysis, pyrolysis is particularly advantageous in the following scenarios:

1. When treating high-organic waste (e.g., waste plastics, rubber tires, oil sludge etc.), pyrolysis achieves efficient resource recovery while reducing environmental pollution.

2. In regions with strict environmental regulations and high pollutant emission standards, pyrolysis's low-emission characteristics make it the preferred choice.

3. For decentralized waste treatment needs, pyrolysis equipment can be scaled down for localized treatment, providing flexibility.

Incineration, however, is better suited for:

1. Large-scale waste treatment scenarios where rapid volume reduction is required.

2. Handling waste with high moisture content, such as food waste and municipal solid waste.

Pyrolysis and incineration are two distinct waste treatment technologies, each with its own advantages and limitations. Pyrolysis demonstrates clear superiority in environmental performance, resource recovery efficiency, and applicability to high-organic waste. For the treatment of high-organic waste, pyrolysis technology offers greater potential and aligns more closely with the goals of sustainable development.

DOING pyrolysis machine manufacturer

At DOING Company, we are committed to providing advanced pyrolysis machines that help our clients achieve efficient waste treatment and resource recovery. If you are looking for a sustainable and effective waste management solution, consider the benefits of pyrolysis and contact us to learn more about our innovative pyrolysis machines.

Prev:Nothing

Next:What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

Leave a message

Mobile/Wechat/Whatsapp: