Tyre pyrolysis oil distillation process plant

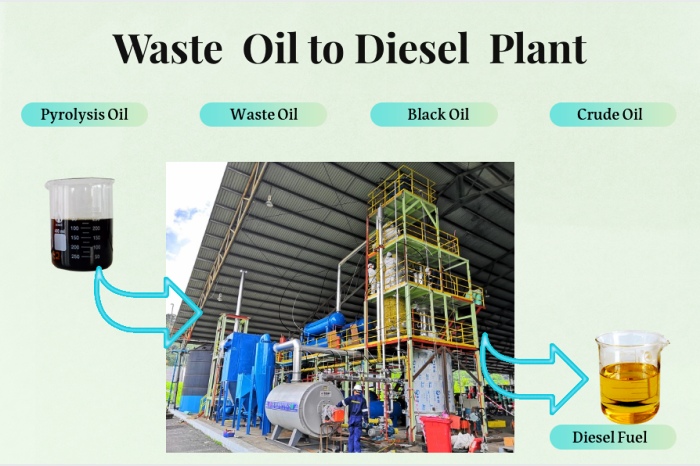

Waste oil distillation process plant is designed for distilling tire pyrolysis oil, plastic pyrolysis oil, lubricating oil and the other heavy oil. The distilling oil can be seen as non-standard diesel, which can be used as fuel for heavy machines and diesel generator. There are many kinds of waste oil could be refined to diesel oil, such as pyrolysis oil, waste oil, black oil, crude oil and so on.

Waste pyrolysis oil to diesel distillation process plant

Waste pyrolysis oil to diesel distillation process plant

DOING GROUP has 13 years experience on tyre pyrolysis oil distillation process plant. Based on customer needs and relevant policies, there are two types of distillation machine we design, one is the normal design waste oil distillation plant with acid-alkali washing technology, and the other one is the new design waste oil distillation plant with solid catalyst technology.

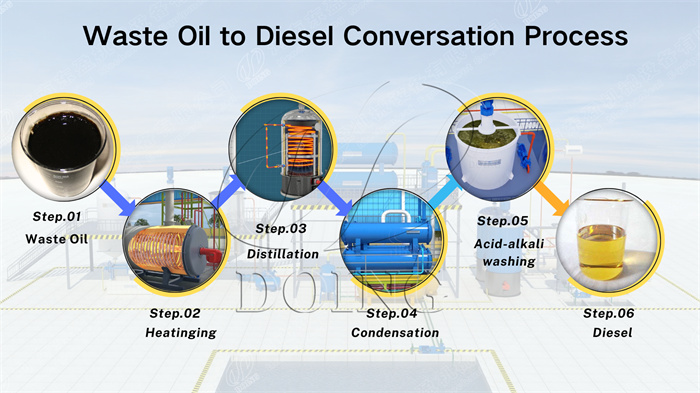

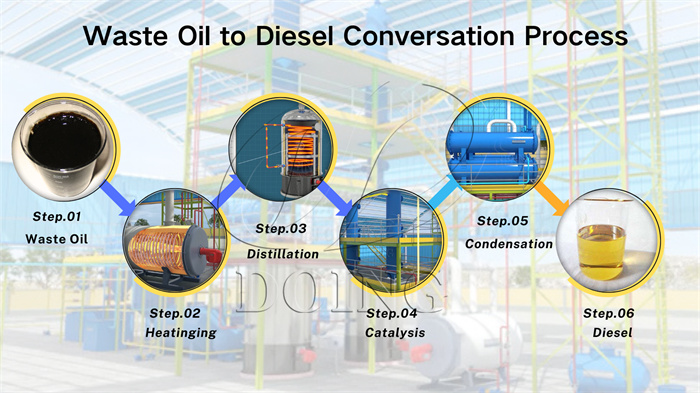

The common working process of these two types of tyre pyrolysis oil distillation process plants mainly includes four steps: heat, condensation, refining and decolorization. But the detailed processes and configuration of these two kinds of waste oil distillation process plants are different. In order for you to have a better understanding of our tyre pyrolysis oil distillation process and equipment details, I will give you a brief introduction.

Waste tyre pyrolysis oil distillation machine

Waste tyre pyrolysis oil distillation machine

The processing capacity of the normal design waste oil distillation plant is 0.1, 0.5, 1, 3, 5, 7, 10, 14tons/day. The tyre pyrolysis oil is heated in the distillation reactor to obtain clean oil gas and sediment impurities, and then clean oil gas is condensed into liquid oil. Then the liquid fuel oil will go through acid and alkali washing to further remove the impuries and improve quality.

Features: This kind of tyre pyrolysis oil distillation process plant is cost effectively, which is suitable for customers who has relatively low investment budget and can purchase acid and alkali easily.

Waste tyre pyrolysis oil distillation process plant with acid and alkali design

Waste tyre pyrolysis oil distillation process plant with acid and alkali design

The processing capacity of the new design waste oil distillation plant is 5, 7, 10, 14tons/day. The first step is the same as the normal design waste oil distillation plant: heating the waste tyre pyrolysis oil to distill oil gas. The second step is catalyzing the oil gas produced by heating in catalytic tower with two patented catalysts. The third step is to condense the catalytic oi gas into oil.

Features: This new design waste tyre pyrolysis oil distillation process plant has higher automation degree and processing efficiency than normal design. But it costs higher than normal design.

Waste tyre pyrolysis oil distillation process plant with solid catalyst design

Waste tyre pyrolysis oil distillation process plant with solid catalyst design

The quality of extracted diesel fuel from these two kinds of machines are similar. The difference between the normal design and the new design waste oil distillation plants lies in that the distilled oil gas will go to the catalytic tower for refining replacing acid and alkali washing.

Noted: If you have higher requirements for oil color, we can equip the diesel decolorization device, which uses bleaching clay to remove color and produce bright diesel.

No matter what kind of machine you choose, we can meet your needs, because our tyre pyrolysis oil distillation process plants have been exported to over 60 countries, such as India, Malaysia, South Africa, Thailand, Mexico, Nigeria, Australia, England, and Pakistan and won the praise and good feedback of customers. We are familiar with the situation and policy around the word. Here is the operation video of waste tyre pyrolysis oil distillation process plant in South Africa.

If you are interested in our tyre pyrolysis oil distillation process plant and want to know more information such as pirce lists, plant planning, etc,. welcome to contact us.

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

Leave a message

Mobile/Wechat/Whatsapp: