What are the technical characteristics of waste tire pyrolysis plant?

Henan Doing is a manufacturer dedicated to the research and development of environmentally friendly renewable energy recycling equipment. For many years, it has been the leader in the industry with its high-quality products, excellent service and good reputation. Henan Doing waste tire pyrolysis plant can pyrolyze waste tire into fuel oil, carbon black ,steel wire and uncondensable gas.

Waste tire pyrolysis plant

Waste tire pyrolysis plant

The waste tire pyrolysis plant developed by Henan Doing has the following technical characteristics:

Stable operation of the equipment:

1. The negative pressure device keeps the pressure of the reactor stable to prevent the backflow of oil gas.

2. Sufficient stabilization devices such as thermometers, pressure gauges, and stabilization valves.

3. It is very dangerous to burn off the exhaust gas containing C directly without other stabilization measures. In our waste tire pyrolysis plant, this part of the exhaust gas first passes through a stabilizer and then enters the stabilizer burner. Before the exhaust gas is burned, ensure the stable operation of the equipment.

Safety devices

Safety devices

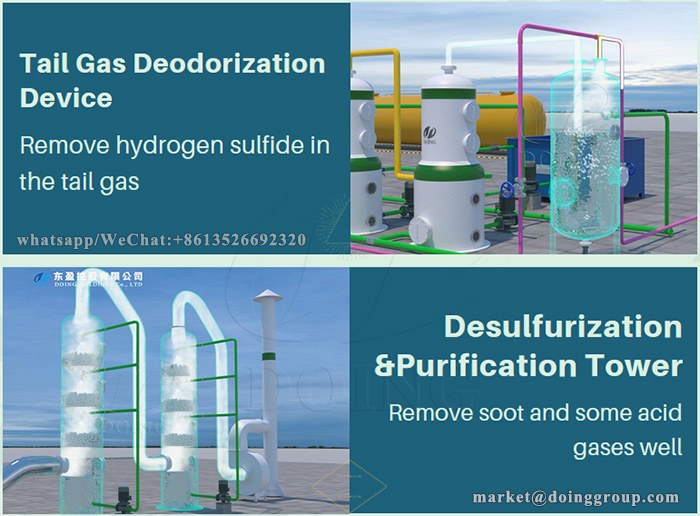

Environmental protection of the equipment:

1. The smoke cleaning system can effectively remove harmful substances in the smoke, such as sulfide, so that the smoke can meet the international gas emission standards.

2. The uncondensable but combustible tail gas can be used to heat the pyrolysis reactor after being processed by the tail gas cleaning system, without gas pollution and saving fuel.

3. The interface of the pyrolysis reactor is sealed with a special sealing material to avoid dust pollution.

Environmental protection system

Environmental protection system

Long service life of the equipment:

1. The reactor material is made of Q245R special steel plate with a thickness of 16mm, which can operate at high temperature for a long time;

2. The pyrolysis reactor adopts automatic welding, the welding place is flat and tight, and the X-ray flaw detection technology, which maximizes the service life of the reactor.

3. The service life of the reactor is generally 8-10 years.

Pyrolysis reactor

Pyrolysis reactor

Energy saving of the equipment:

1. The system is well sealed, there is no gas leakage, thus it saves fuel and greatly improving the work efficiency.

2. The tail gas is recycled to heat the reactor to save fuel and cost.

Besides, our waste tire pyrolysis plant has passed the Europe and American Environmental protection standards and our pyrolysis plant can process not only waste tire, but also waste plastic. If you want to know more information about our pyrolysis plant, welcome to consult us feel free.

Prev:What is the best solution to white pollution? Which one is the best?

Next:What’s the workflow of the waste oil distillation machine?

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

Leave a message

Mobile/Wechat/Whatsapp: