What is the price of continuous tyre pyrolysis plant?

When you plan to buy a machine, the price of this machine should be a very important factor you need to consider, then what is the price of continuous tyre pyrolysis plant? This is not a specific figure, but is influenced by the following factors.

Model of the continuous tyre pyrolysis plant

The daily capacity of our continuous tyre pyrolysis plant is 20T, 30T, 50T, and different model has the different price. If your scale is not very large, you can choose our continuous tyre pyrolysis plant with a capacity of 20T for production. When you have got benefit and need to expand the scale, you can consider 50T continuous tyre pyrolysis plant.

DOING 20T continuous tyre pyrolysis plant

DOING 20T continuous tyre pyrolysis plant

Configurations of continuous tyre pyrolysis plant

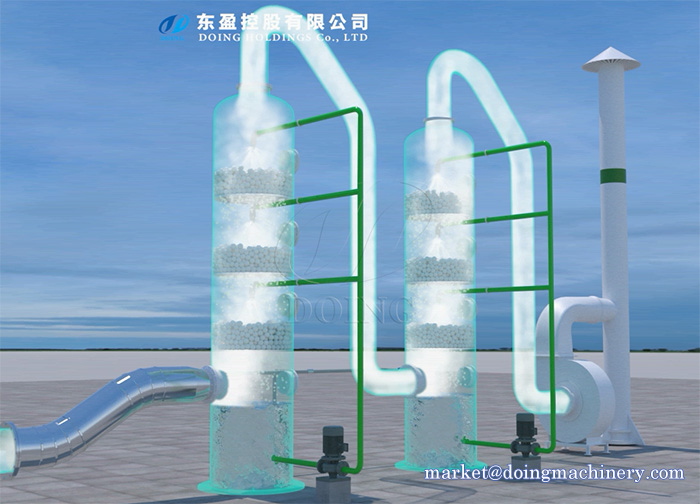

We have standard configuration and high configuration. High configuration is based on the standard configuration plus environmental protection machine, and burners and ect. So the price of high configuration continuous tyre pyrolysis plant is higher than standard configuration.

Environmental protection machine of continuous tyre pyrolysis plant

Environmental protection machine of continuous tyre pyrolysis plant

Supplier type

Usually, to buy such a large piece of continuous tyre pyrolysis plant, you need to choose the manufacturer of the machine, rather than an intermediate trader. Choose a machine manufacturer and you will be able to buy at a lower price, with after-sales support and technical support. Take our company as the example, as a professional machinery manufacturer, DOING will provide our customers with on-site installation services, equipment commissioning and operator training.

DOING company and factory

DOING company and factory

To sum up, when you ask about what is the price of continuous tyre pyrolysis plant, you need to clarify your specific requirements and tell us your budget. We can design the configuration plan for you according to your budget.

If you are interested in our continuous tyre pyrolysis plant, please contact us or leave your email address and whatsapp number to us, our seals manager will contact you within 24 hours.

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

Leave a message

Mobile/Wechat/Whatsapp: