Can waste plastic be turned into fuel?

Waste Plastic is a product of the humanpetrochemical industry, which itself contains many hydrogen atoms. Withthe right pyrolysis and catalysis, these hydrogen atoms of wasteplastics can be recycled and turned into valuable fuels.

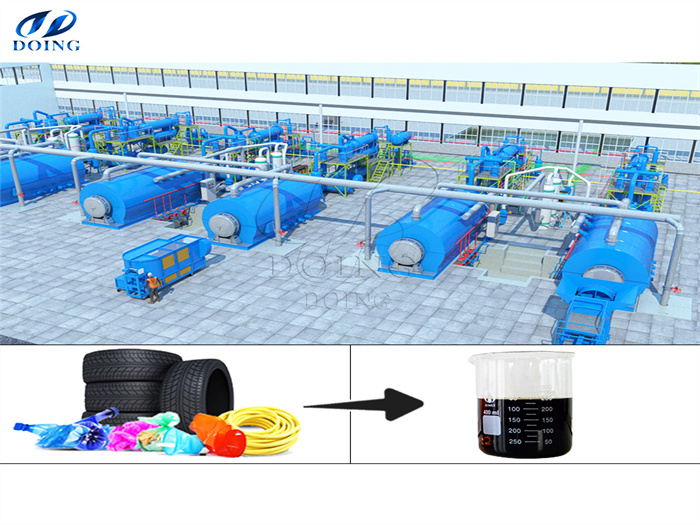

Waste plastic to fuel oil pyrolysis plant

Manycommon waste plastics in life are recyclable, such as PP, PE, PS, ABS,PET bottles, bottle caps, straws, microwave food boxes, disposableplastic cups, packaging boxes, white plastic sheets, instant noodlespackaging bags, plastic trademarks, paper mill scraps, plastic householdwaste, plastic cable skins, plastic bags, etc.

All these wasteplastics can be pyrolyzed into fuel oil and carbon black throughpyrolysis plant, but the fuel oil outputs will vary with the types ofplastic. The specific plastic oil output list is as follows, for yourreference.

Different plastics materials have different oil yield

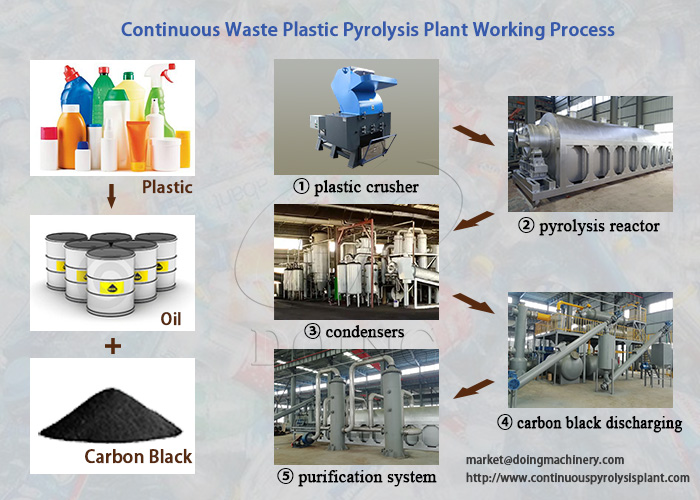

So how is this waste plastic to fuel oil recycling process achieved? Let's go into details.

First,the waste plastic is sent to the pyrolysis reaction of the waste plastic pyrolysis plant; then the oil gas will be generated when it isheated to the required temperature.

Then the condensation systemof the waste plastic pyrolysis plant is used to condense the oil gasinto liquid oil and store it in the oil tank. It's worth mentioning thatDOING waste plastic pyrolysis plant is equipped with the mostprofessional industrial condensors, which can fully guarantee the highoil yield and help you obtain the maximum profits. And the solid carbonblack will remain in the reactor and be discharged through thedischarging system.

The process of waste plastics to oil plant

Besides that, there are also somenon-condensable gas, which should be purified by the exhaust gaspurification device. The purified gas can be directly recycled and usedto save fuel.

The waste plastic pyrolysis plant realizes the 100%recycling of waste plastics by converting waste plastics to usefulproducts in a green way, which brings social and economic benefits. Ifyou want to know the detailed designs of waste plastic pyrolysis plant,equipment quotation and related project implementation solutions, pleaseinitiate an inquiry!

Prev:How to make crude oil from waste plastic?

Next:Can you convert plastic into fuel oil? What machine can be used?

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line