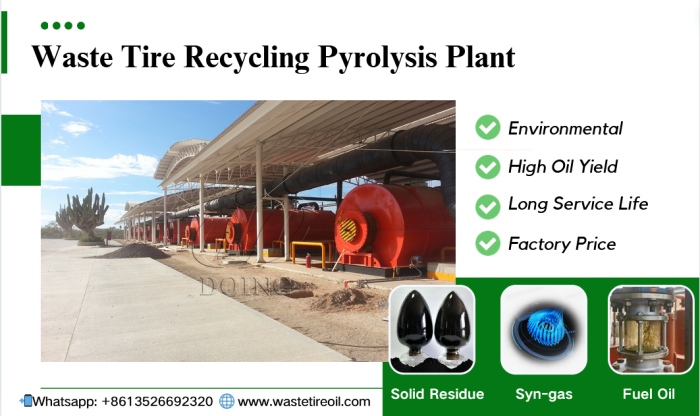

Waste tire pyrolysis equipment

Waste tire pyrolysis equipment is magical which is produced by DOING that can make waste tires into precious oil. It sounds unbelievable, but that is a fact. Now let us explore waste tire pyrolysis equipment together.

Waste tire pyrolysis equipment

Waste tire pyrolysis equipment

The process of waste tire pyrolysis equipment handing waste tire is not that complicated. But it should follow specific process and specification.

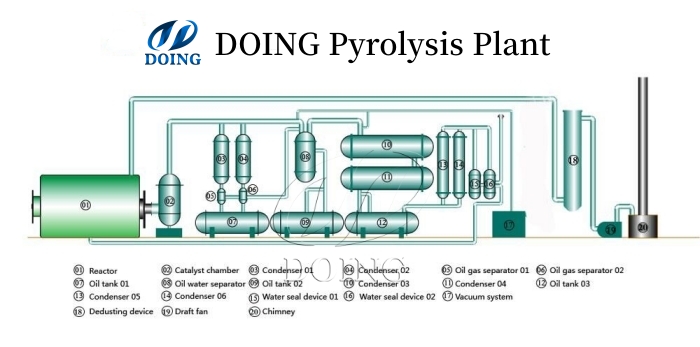

The process of DOING handling waste tire are as follows:

The process of waste tire pyrolysis equipment

The process of waste tire pyrolysis equipment

1.Put waste tires into a sealed pyrolysis reactor. You can feed it by manual worker or by auto-feeder.

Waste tire auto feeder for pyrolysis equipment

Waste tire auto feeder for pyrolysis equipment

2.Heating the sealed reactor that can make macromolecule into small molecule, then waste tires are pyrolyzed into oil gas, uncondensable gas and carbon black, and if raw material is waste tire, it will have steel wire.

3.Cooling. The oil gas can be cooled down to oil which usually be called pyrolysis oil through a water circulating cooling system which is a important part for the waste tire pyrolysis equipment. Pyrolysis oil has many applications, such as be used in steel factory, boiler heating, heavy oil generator, cement factory. Go a step further, the application of pyrolysis oil is refined into diesel. DOING also provide waste oil refining equipment. The diesel can be used in diesel generator or heavy machinery or being a diesel fuel for heating. There are great economic benefits for investor.

4.Exhaust gas recovery and utilization. The uncondensable gas is usually recycled to heat the reactor or collected as a fuel. This action reduce air pollution to a great extent. It is good for our life. This is what the government strongly advocates.

5. Discharging carbon black and steel wire. Carbon black can be made into pellets for burning and heating, or be refined to making new rubber products, for example, making new tire, shoe soles, paint and so on. In a manner of speaking, these products are everywhere in our life. Steel wire could be sold as scrap to the recycle bin or steel mill for remelting. That's also a benefit for investor.

Products of waste tire pyrolysis equipment

Products of waste tire pyrolysis equipment

So down, everything has its place. Ensuring that nothing gets wasted is the biggest advantage of this waste tire pyrolysis equipment. The arrival of pyrolysis equipment has turned waste tires into money truly.The most significant aspect of the whole production process is simple and non-pollution. Waste tire pyrolysis equipment not only help us handle house refuse to making our living environment better but also provide precious energy ,oil.As we all know energy is limited, so waste tire pyrolysis equipment is far-reaching significance for us. It will be a future trend for the whole world to use waste tire pyrolysis equipment.

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line