What product can be obtained from recycling waste plastic?

The molecules of different plastic are very different, so the final product and oil yield are different. Generally, there are four kinds of final products that can be obtained from recycling plastics: hydrocarbon gas(C1-C5), oil (gasoline is C5- C11, diesel oil is C12-C20, the heavy oil is C20), paraffin and coke.

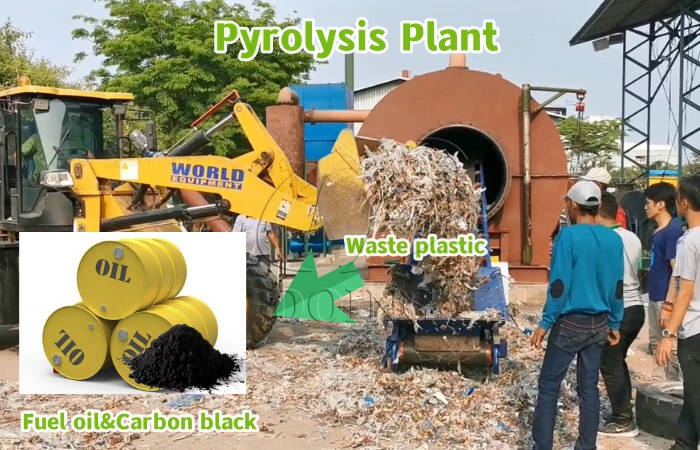

Based on the recycling of waste into energy and reuse, Henan Doing Environmental Protection Technology Co., Ltd. has developed and designed pyrolysis machines for recycling waste plastics into industrial fuel oil, carbon black, syngas, etc.

Waste plastic to fuel oil and carbon black pyrolysis plant

Waste plastic to fuel oil and carbon black pyrolysis plant

How does the pyrolysis machine work to recycle waste plastics into oil? Here is the working process:

1. Feeding part

Fill the reactor with waste plastic.

2. Pyrolysis part

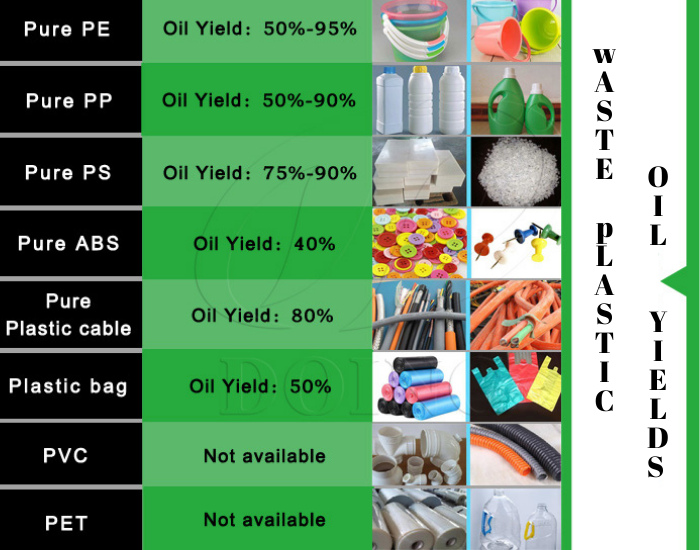

In this process, the temperature in the reactor gradually increases. When the temperature gets high to a certain extent and the waste plastic will be decomposed and oil gas will come out. Totally about 40% -80% fuel oil comes out from waste plastic, mainly depends on the plastic types. Also, there is about 10% condensable gas that can go back to the reactor as the heating fuel after purification.

Different oil yileds of different plastics

Different oil yileds of different plastics

3. Cooling reactor part

The DOING pyrolysis machine is equipped with 8 tuyeres to extract the hot air, so that the reactor is quickly cooled and ready for next pyrolysis process, which is efficient.

4. Discharge carbon black part

In total, you can get about 15%~30% carbon black.

DOING Company has been focusing on the research and development of waste plastic pyrolysis machines for more than 13 years, constantly innovating production technology, and strictly controlling the production quality of machines. The plastic pyrolysis technology and operation of DY pyrolysis machines are easy, safe and stable. And our pyrolysis machines have passed GB/T 19001-2016/ISO 9001:2015 international quality system certification, EU CE certification and SGS certification. Please feel free to send us your inquiry if you are interested.

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line