Home>News>Industry News>Recycling and treatment method of waste toothpaste tubes - pyrolysis technology

Recycling and treatment method of waste toothpaste tubes - pyrolysis technology

Toothpaste is a daily necessity and its consumption is huge. As a result, a large number of waste toothpaste tubes are generated. If these wastes are not properly handled, they will cause considerable pressure on the environment. In recent years, pyrolysis technology, as an effective method for treating waste plastics, has also been tried to be applied to the recycling and treatment of waste toothpaste tubes, other similar waste plastic materials and solid waste, etc.

Waste pyrolysis technology applications

Waste pyrolysis technology applications

The material of waste toothpaste tubes is mainly a composite structure of plastic and metal aluminum. Among them, the plastic part is mostly polymer materials such as polyethylene (PE) or polypropylene (PP), while the metal part is made of aluminum. While this composite structure protects the toothpaste from pollution, it also brings certain challenges to the recycling and treatment after disposal. Traditional recycling methods often find it difficult to effectively separate plastics and metals, resulting in low recycling efficiency.

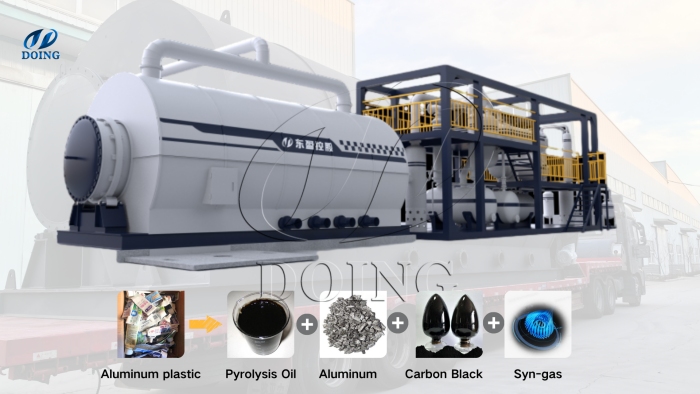

Pyrolysis technology provides a new solution. During the pyrolysis process, the plastic part of the waste toothpaste tube can be decomposed into small molecular hydrocarbon gas, liquid and residue in a high-temperature oxygen-free or low-oxygen environment. These decomposition products can be further condensed and separated to obtain high-value-added products such as plastic pyrolysis fuel oil, carbon black and syn-gas. The metal aluminum part remains unchanged during the pyrolysis process and can be easily separated from the residue for further recycling.

Waste toothpaste tubes recycling pyrolysis machine

Waste toothpaste tubes recycling pyrolysis machine

The pyrolysis technology is well matched with the material of the waste toothpaste tube. Plastic materials such as polyethylene and polypropylene are easy to crack at high temperatures, and the pyrolysis products have high economic value. At the same time, as a high-value metal, the recycling and reuse of aluminum is also of great significance. Through pyrolysis technology, the plastic and metal in the waste toothpaste tube can be effectively separated and recycled, realizing the maximum utilization of resources.

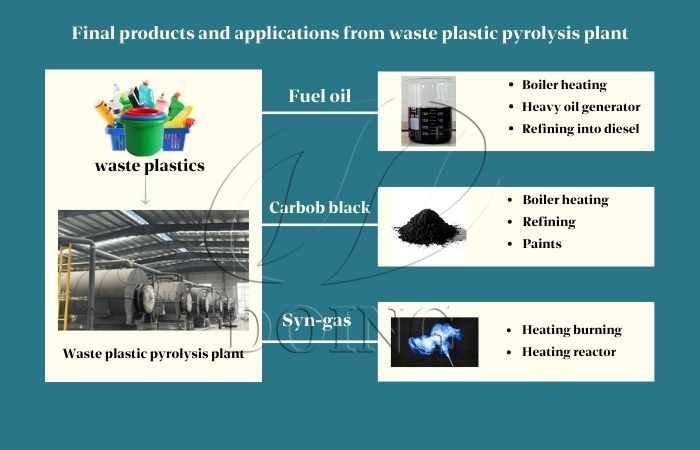

The advantages of pyrolysis technology in recycling waste toothpaste tubes are its high efficiency and environmental protection. Traditional recycling methods often require complex physical or chemical treatment processes, while pyrolysis technology can simultaneously achieve the decomposition of plastics and the recovery of metals in a relatively simple reaction process. In addition, the fuel oil and gas produced in the pyrolysis process can be used as energy, and carbon black can be used as filler or further processed into other products, thereby achieving waste reduction, resource utilization and harmlessness.

Waste plastic pyrolysis machine final product usages

Waste plastic pyrolysis machine final product usages

From the perspective of convenience, the operation of pyrolysis technology is relatively simple, the equipment investment cost is moderate, and it can adapt to the treatment needs of waste toothpaste tubes or together with other waste plastic materials of different scales. Whether it is a large recycling center or a small family workshop, you can choose the appropriate waste plastic pyrolysis machine and process parameters to recycle the waste toothpaste tubes according to the actual situation.

In summary, pyrolysis technology, as an emerging method for recycling waste toothpaste tubes and similar waste aluminum plastic or plastic materials, has broad application prospects and significant economic benefits. Through pyrolysis technology, we can turn waste toothpaste tubes into treasures, realize the sustainable use of resources and environmental protection.

Welcome all the customers to send us your detailed requirements for customizing a suitable waste plastic pyrolysis solution! Henan Doing Company has accumulated rich pyrolysis machine R&D and installation experience to help you achieve your goal!

Prev:What are the emissions from tyre pyrolysis plants? Can it meet environmental standards?

Next:Can pyrolysis plant be used to recycle waste oil into diesel?

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

Leave a message

Mobile/Wechat/Whatsapp: