How much does plastic to oil machine cost?

The captial price of DOING plastic to oil machine vary from USD12,000 to USD400,000+, which will greatly depend on its model, handling capacity as well as the configuration.

If you are interested in getting a detailed quotation price for a plastic to oil machine, it is better to be clear in mind how many tons of plastic you are going to process per day, and what kind of standard you hope the plastic to oil machine can reach, then with all the above information, our sales manager can provide the best solution and offer it to you very quickly.

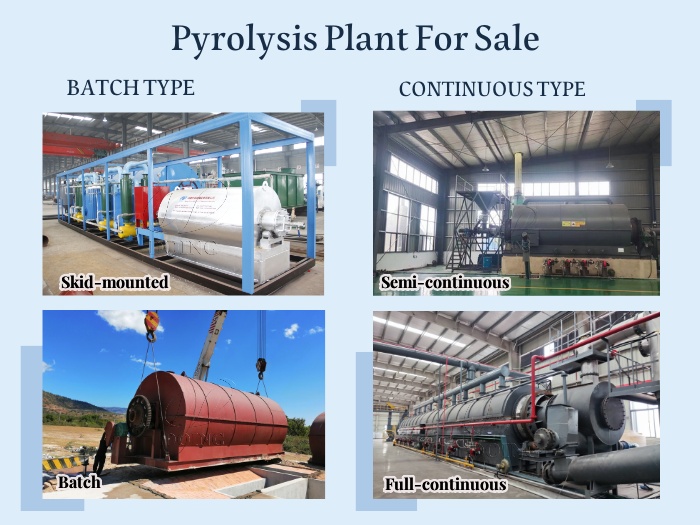

Different models of plastic to oil machine for sale

Different models of plastic to oil machine for sale

Now our plastic to oil machine has mainly three different types- batch one, semi-automatic one and fully automatic one based on their degree of automation and operation process. The processing capacity of our batch plastic to oil machine ranges from minimum 100kg/batch to the maximum 20ton/day, and the cost varies from USD12000 to>USD70,000. The normal processing capacity of our automatic plastic to oil machine is above 20ton and maximum capacity 50ton/day, and the cost is above usd400,000. The cost of semi-automatic one is just between batch one and fully automatic one.

Firstly, you can confirm your daily processing capacity of waste plastic. If lower than 15ton, you will have to consider our batch plastic to oil machine. And then, you need to decide which configuration of plastic to oil machine to install according to your budget range and the actual situation. If the labor is expensive and the environment standard is also very high, the automatic plastic to oil machine and batch one with high configuration will be the right choice and vice versa.

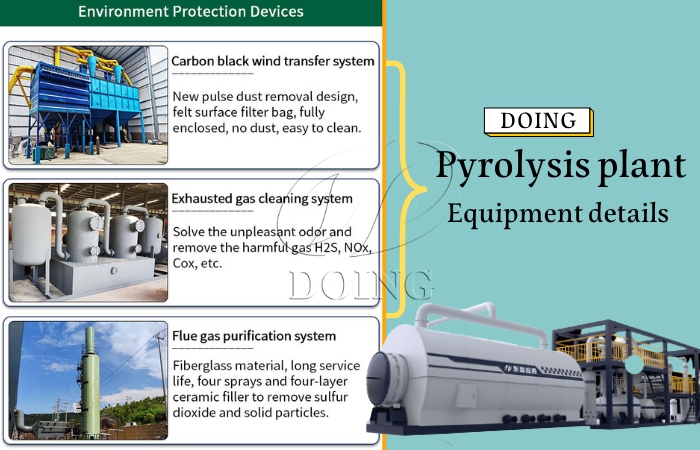

High configuration environmental plastic to oil machine

High configuration environmental plastic to oil machine

The above are the tips for you to get the cost of our plastic to oil machine in the shortest time. Hope they are helpful to you. For more information about our plastic to oil machine, please do not hesitate to send your enquiry, and we can customize it for you at a favorable factory price!

Prev:What is the estimated life expectancy of pyrolysis plant?

Next:Transforming Waste into Energy: How to Set Up a Pyrolysis Plant?

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line