Home>News>Industry News>Plastic Waste Management in the Czech Republic and Pyrolysis Recycling Technology Solutions

Plastic Waste Management in the Czech Republic and Pyrolysis Recycling Technology Solutions

As an EU member state, the Czech Republic has made significant progress in environmental protection and sustainable development, but plastic waste management still faces severe challenges. According to statistics, up to 45% of the plastic waste generated annually in the Czech Republic is directly landfilled, and 17% is incinerated. This traditional method not only occupies valuable land resources but also leads to greenhouse gas emissions and soil pollution. Landfilling perpetuates plastics in the environment, while incineration releases harmful carbon dioxide and toxins, violating the goals of the EU's Circular Economy Action Plan.

Faced with this situation, advanced plastic recycling technologies urgently need to be promoted. Pyrolysis technology, as a thermo-chemical conversion method, decomposes waste plastics into reusable products such as oil, gas, and carbon black by heating them under anaerobic or low-oxygen conditions, providing an efficient and environmentally friendly solution.

Pyrolysis machine as waste plastic recycling solution

Pyrolysis machine as waste plastic recycling solution

Current Status of Plastic Waste Management in the Czech Republic

Plastic waste in the Czech Republic mainly originates from packaging, consumer goods, and industrial production. According to data from the Czech Statistical Office (ČSÚ), the country's total plastic waste exceeded 1 million tons in 2022, with thermoplastics such as polyethylene (PE), polypropylene (PP), and polystyrene (PS) accounting for over 70%. However, the recycling rate was only 38%, far below the EU average (approximately 50%).

Landfilling: 45% of waste plastics end up in landfills. This not only wastes resources but also pollutes groundwater and causes methane emissions. The Czech Republic has over 200 active landfills, many of which are nearing saturation, putting increasing pressure on compliance with the EU Landfill Directive.

Waste plastic disposal in Czech Republic by landfill

Waste plastic disposal in Czech Republic by landfill

Incineration: 17% of plastics are incinerated for power generation or heating. While incineration facilities (such as the modern incinerator near Prague) can recover some energy, the process produces pollutants such as dioxins and is energy inefficient. The EU is pushing to reduce incineration and shift towards higher-value recycling pathways.

These methods ignore the chemical value of plastics and fail to achieve the zero waste goal. In contrast, mechanical recycling (such as washing and regranulation) is only suitable for clean plastics and is inefficient when dealing with complex mixed waste. Pyrolysis technology has emerged as a solution, offering a highly compatible and resource-efficient alternative for plastic treatment in the Czech Republic.

Principles and Advantages of Plastic Pyrolysis Recycling Technology

Pyrolysis is a thermal pyrolysis process that heats waste plastics in an oxygen-free environment at 200-500°C, breaking down molecular chains to produce liquid fuels (pyrolysis oil), syngas, and solid carbon black. The main equipment involved is plastic pyrolysis machine(pyrolysis furnace), achieves the waste plastics to energy conversation process.

The biggest highlight of DOING pyrolysis technology is its broad compatibility with raw materials. With a few exceptions, such as polyvinyl chloride (PVC, which releases hydrogen chloride gas) and polyester (PET, which may produce acidic byproducts), pyrolysis can efficiently process most common waste plastics:

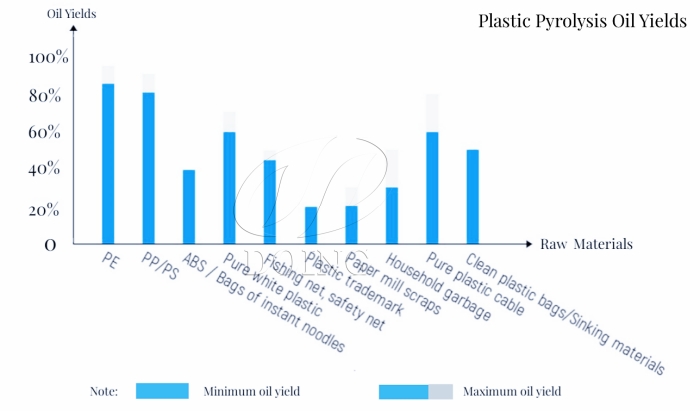

Plastic pyrolysis oil machine supported feedstocks and oil output

Plastic pyrolysis oil machine supported feedstocks and oil output

Thermoplastic plastics: such as polyethylene (PE), polypropylene (PP), and polystyrene (PS), which constitute the largest proportion of waste plastics in the Czech Republic, can be directly converted into high-quality pyrolysis oil with a yield of 70-80%.

Mixed waste plastics: Pyrolysis can process mixed plastics in municipal solid waste (MSW) without pre-sorting, including multi-layer packaging and contaminating plastics. This is particularly suitable for mixed waste streams in the Czech Republic (such as supermarket packaging waste), reducing costly sorting costs.

Other types: Compatible with ABS, aluminum-plastic composites, and even some thermosetting plastics (such as rubber in used tires), expanding the scope of recycling.

Compared to other plastic treatment technologies, pyrolysis technology offers significant advantages as a waste plastic management solution:

Plastic Pyrolysis vs. Mechanical recycling: Mechanical recycling only achieves 50-60% recovery and is susceptible to contamination; pyrolysis achieves up to 90% recovery with high product purity.

Plastic Pyrolysis vs. Incineration: Incineration only produces heat (efficiency<30%), while pyrolysis products can be used as high-value fuels or feedstocks, increasing economic returns by 3-5 times.

Plastic Pyrolysis vs. Landfill: Landfills have zero value output, while pyrolysis achieves a closed-loop resource system, reducing the carbon footprint by approximately 80% (according to EU life cycle assessment).

Furthermore, the waste plastic pyrolysis process operates in a closed loop, with low pollutant emissions, complying with EU and Czech environmental control requirements. Waste Plastic Pyrolysis Machine is available in various specifications, making it convenient for different investors and organizations to choose, with a relatively short payback period.

Comparisons of waste plastic recycling ways

Comparisons of waste plastic recycling ways

As a professional pyrolysis plant manufacturer, Henan Doing Company provides numerous clients with feasible waste treatment pyrolysis solutions and high-efficiency, high-quality waste plastic pyrolysis machine manufacturing and installation, assisting clients in integrating pyrolysis technology into waste management, while achieving waste reduction and resource conversion. If you need efficient and economical waste plastic recycling solutions, please contact us. We are committed to cooperating with Czech partners to provide customized equipment and comprehensive technical support!

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

Leave a message

Mobile/Wechat/Whatsapp: