Home>News>Industry News>How does the waste tire pyrolysis plant deal with the waste gas generated in the production process?

How does the waste tire pyrolysis plant deal with the waste gas generated in the production process?

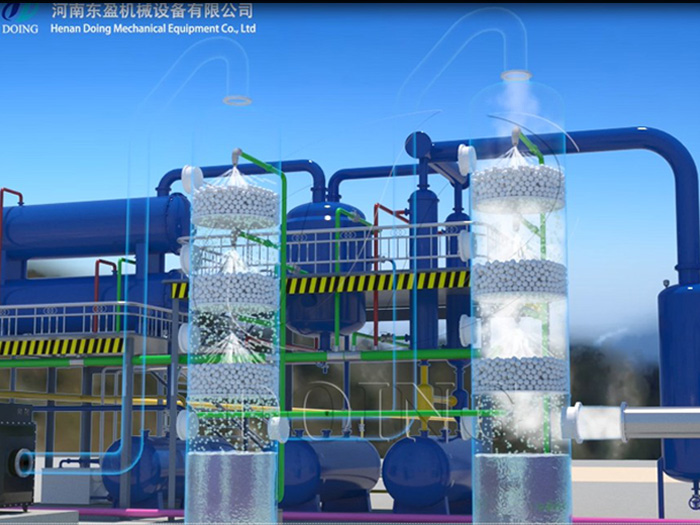

In the past, people used the traditional way to turn the waste tires into oil, which caused a lot of pollution to the environment. But now DOING company's waste tire pyrolysis plant USES advanced pyrolysis technology to better turn waste tires into fuel oil. Moreover, the waste tire pyrolysis plant can specially deal with the smoke and harmful waste gas generated during the production process so that the gas discharged meets the national emission standards.

Waste tire pyrolysis plant can specially process the smoke and harmful waste gas generated during the production process

Waste tire pyrolysis plant can specially process the smoke and harmful waste gas generated during the production process

Waste tire pyrolysis plant can pyrolyze the tires without oxygen, and the tires will be evaporated into oil gas, and the oil gas will be condensed into fuel oil, during this process, the tires is not directly burned, so it will release no harmful gases.

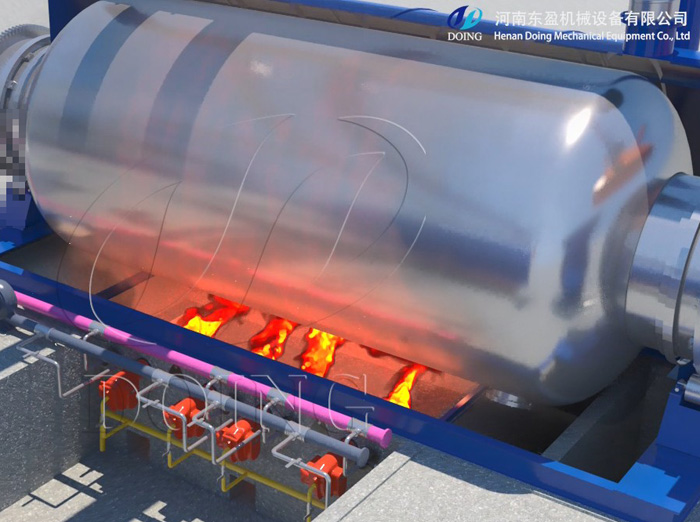

But everything has its advantages and disadvantages. Waste tire pyrolysis plant needs to be heated by fire, so different heating materials will have different emissions. If you use coal or wood as fuel, there will be some soot after combustion, but there are different types of smoke dedusting system in our plant to clean the smoke, and reduce the impact to the air. However, you can choose natural gas or pyrolysis fuel oil as the fuel for the heating the reactor, which can meet the emission standards of China and Europe.

Syn-gas as the fuel for the heating the reactor

Syn-gas as the fuel for the heating the reactor

In addition, during the pyrolysis process, there will be some non-condensable combustible gas, usually called “syn-gas”, and the syn-gas will be recycled for the heating of the reactor, but these syn-gas contain some toxic gases. If it is used directly without treatment, it will also cause some environmental pollution. We have the special deodorization system for this syn-gas, which can remove the harmful gases in the syn-gas and then use it to heat the reactor.

DOING company is committed to the research and production of environmental protection waste tire pyrolysis plant, and we are open to cooperate with anyone who are interested in this career.

Prev:Why choose the continuous waste tyre pyrolysis plant to deal with waste tyres?

Next:Indian customer feedback on government issues latest report on tyre pyrolysis industry

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

- What are the types of materials pyrolysis equipment can process?

Leave a message

Mobile/Wechat/Whatsapp: