Home>News>Enterprise News>Congratulations! Two sets of 15TPD semi-continuous waste plastic pyrolysis plants were delivered to India!

Congratulations! Two sets of 15TPD semi-continuous waste plastic pyrolysis plants were delivered to India!

Good news! On May 8, 2024, DOING factory finished the delivery of two sets of 15TPD waste plastic pyrolysis plants to India with responsible and patient inspection and packaging. And these packaging and delivery pictures and videos will also be sent to our Indian customer.

Delivery pictures of waste plastic pyrolysis plants to India

Delivery pictures of waste plastic pyrolysis plants to India

Our Indian customer is engaged in the waste plastic recycling industry, having abundant waste plastic resources, such as the PP/PE plastics and plastic household garbage, which all are good resources to be used in waste plastic waste plastic pyrolysis plants to get useful products. After deciding to set up the waste plastic pyrolysis plant project, the Indian customer made detailed comparisons for many waste plastic pyrolysis plant manufacturers, and finally proposed cooperation requirements to DOING. According to the real feedback of the Indian customer, "unlike other waste plastic pyrolysis plant manufacturers, DOING sales manager made several detailed schemes based on the our actual situation and machine types of DOING researched, and displayed both the advantages and disadvantages of all these schemes for our reference." That's also one important factor for the Indian customer to reach the final cooperation with DOING.

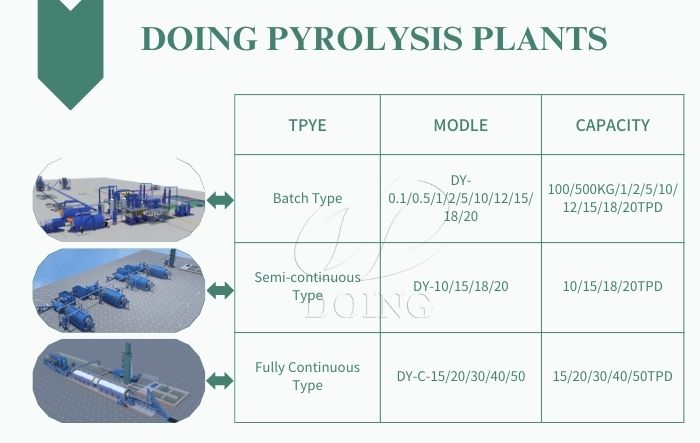

Three types of waste plastic pyrolysis plants of DOING

Three types of waste plastic pyrolysis plants of DOING

The semi-continuous waste plastic pyrolysis plant ordered by the Indian customer has the unique design to enhance work efficiency, which can finish three batches of processing within two days, and can discharge final products without cooling the reactor to save much work time compared with the batch-type waste plastic pyrolysis plant. And our semi-continuous waste plastic pyrolysis plant adopts the water tank cooling system, which has high cooling effect while avoiding any water pollution.

About twenty days later, these two sets of 15TPD waste plastic pyrolysis plants will arrive in India, and then our engineer will provide technical and professional guidance and training to help our Indian customer set up the waste plastic pyrolysis plant project as soon as possible.

Projects display of DOING pyrolysis plants

Projects display of DOING pyrolysis plants

In the Indian market of waste plastic pyrolysis plant, DOING has occupied a certain position, and we have cooperated with many Indian customers on our waste plastic pyrolysis plants of various types, from skid-mounted batch type to the fully continuous type, which all received great feedback. And in addition to India, we also have friendly cooperation with our customers in other countries, such as Malaysia, Indonesia, Brazil, Russia, Mexico, Ghana, Colombia, Pakistan, Thailand, Vietnam, etc. If you also want to set up similar projects in your countries, just feel free to contact us!

Prev:Four sets of semi-continuous plastic to oil pyrolysis plants were shipped to Vietnam!

Next:Shipping news! A set of movable waste plastic pyrolysis machine was shipped to India!

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

- What are the types of materials pyrolysis equipment can process?

Leave a message

Mobile/Wechat/Whatsapp: