Home>News>Enterprise News>DOING 10TPD Batch Plastic Pyrolysis Machine Secures Order from Indonesian Customer

DOING 10TPD Batch Plastic Pyrolysis Machine Secures Order from Indonesian Customer

In August 2025, DOING Company, a manufacturer of pyrolysis machines and waste oil refining equipment, signed a contract with an Indonesian enterprise specializing in waste and hazardous material recovery. The deal involves suppling a 10TPD batch plastic pyrolysis machine tailored to the customer's operations. This Indonesian customer, focused on recycling various waste streams, plans to use the pyrolysis oil produced by the pyrolysis machine as fuel for their own factory processes, integrating it directly into their production cycle.

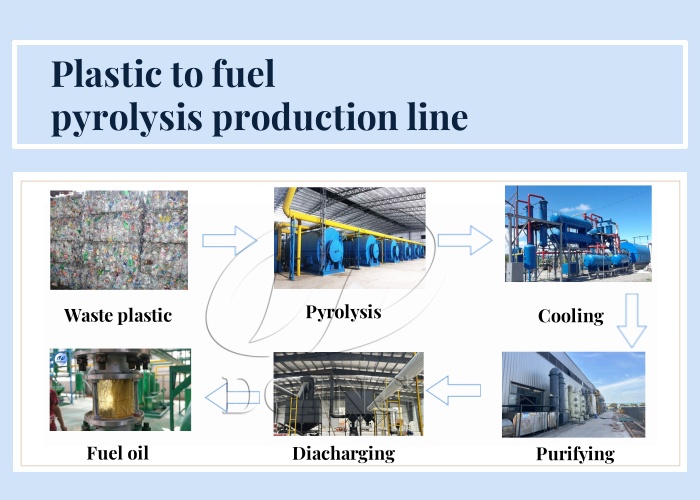

Plastic pyrolysis to fuel oil production line

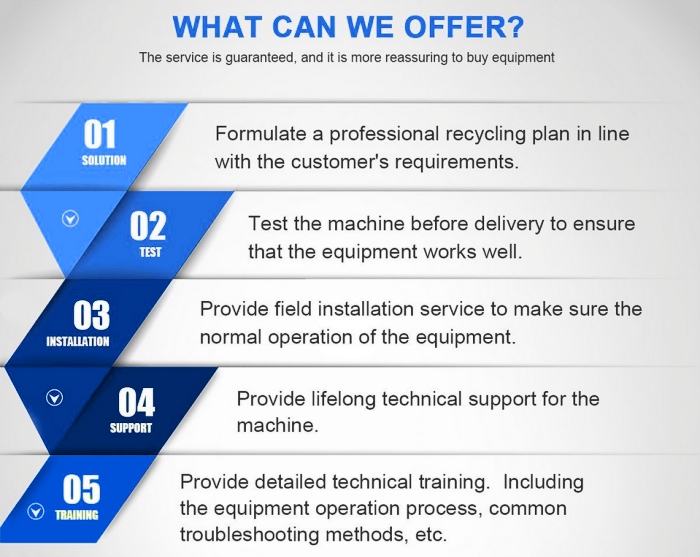

Having visited DOING's facilities earlier, the Indonesian customer conducted an in-depth inspection of DOING pyrolysis machine's construction, processing workflow, and on-site performance. They paid close attention to how the machine handles real-world waste inputs and delivers consistent outputs. Throughout the discussions, DOING provided prompt responses to their inquiries on technical details and operational setup. This ongoing communication built trust between both parties, ultimately leading the customer to confirm that the 10 TPD batch pyrolysis machine met their needs. Furthermore, because DOING Company offered a competitive price that fit the customer's budget, an agreement was quickly reached.

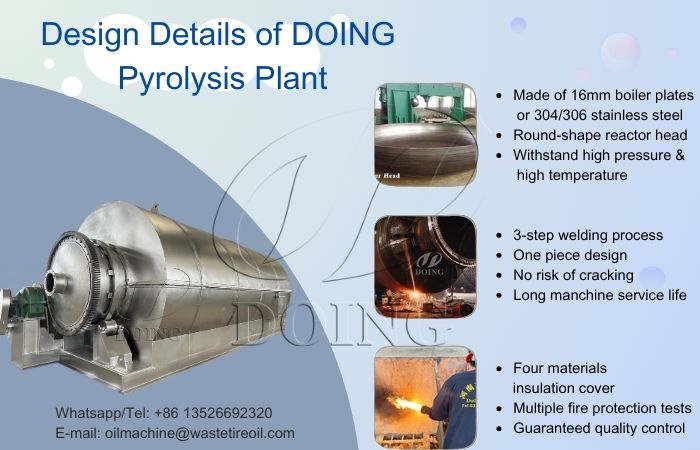

Design details of DOING pyrolysis machine

At the heart of this partnership is DOING's 10TPD batch plastic pyrolysis machine, skilled to address the specific challenges of waste recovery operations like those of the Indonesian client. The pyrolysis machine excels in processing a range of waste plastics commonly collected in recycling businesses, such as mixed polyethylene, polypropylene, and other non-hazardous polymers. Its flexible feeding system can accommodate waste materials of different sizes and shapes, and requires minimal pre-sorting—a practical advantage for companies that handle various types of waste.

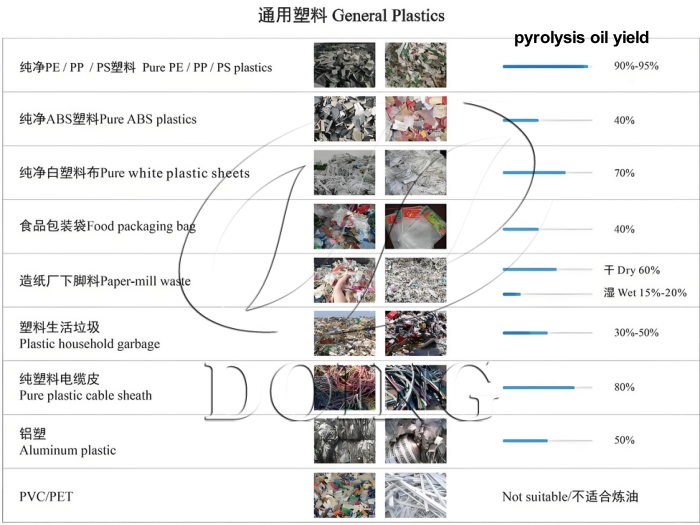

Types of plastics that can be processed by pyrolysis and their oil yield

The pyrolysis process converts these plastics into usable oil through controlled heating in an oxygen-free environment, yielding a high-quality fuel oil suitable for industrial burners. For this customer, the pyrolysis machine's output—typically 40-50% oil yield per batch—matches their factory's alternative fuel demands, providing a steady supply for industrial boiler/furnace heating uses. This pyrolysis machine operates in batches of 10 tons per day, allowing for production scheduling to be synchronized with the receipt of waste materials from customers. The resulting plastic pyrolysis oil has good combustion properties and is a reliable alternative to traditional fuels. Furthermore, the syngas produced during the pyrolysis process can be recycled to heat the pyrolysis reactor, effectively reducing reliance on external energy sources.

The batch design is particularly suitable for operations of the scale typical of Indonesian clients. Unlike continuous systems, it features a simpler reactor structure with fewer moving parts, simplifying daily operations for medium-sized recycling companies and consequently reducing training requirements for operators. Maintenance is also relatively simple, effectively controlling long-term costs—a key consideration for cost-conscious clients.

DOING plastic pyrolysis machine manufacturer

This 10TPD batch plastic pyrolysis machine will soon help this Indonesian customer convert collected plastic waste into usable energy for their factory, making their waste recycling operations more efficient. DOING will also continue to monitor the progress of this project and provide necessary technical support to ensure the pyrolysis machine operates stably and efficiently.

Prev:Nothing

Next:Indian Customer Purchased 2 Units of DOING 15TPD Semi-Continuous Plastic Pyrolysis Machine

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

Leave a message

Mobile/Wechat/Whatsapp: