Can vehicle bumpers be recycled using the pyrolysis process?

Yes, vehicle bumpers can be recycled using the pyrolysis process. Here let's give a brief introduction to this topic.

1. The pyrolysis principle of vehicle bumpers by pyrolysis plant

Pyrolysis is a thermal decomposition process in which the raw material ( organic wastes like waste rubber tyre, plastic, in this case vehicle bumpers) uses heat to break the chemical bonds of large molecules in the waste material in the absence of complete oxygen or limited oxygen supply. The process of converting it into low molecular weight liquid fuel oil, combustible gas (hydrogen, methane, carbon monoxide mixture) and solid carbon.

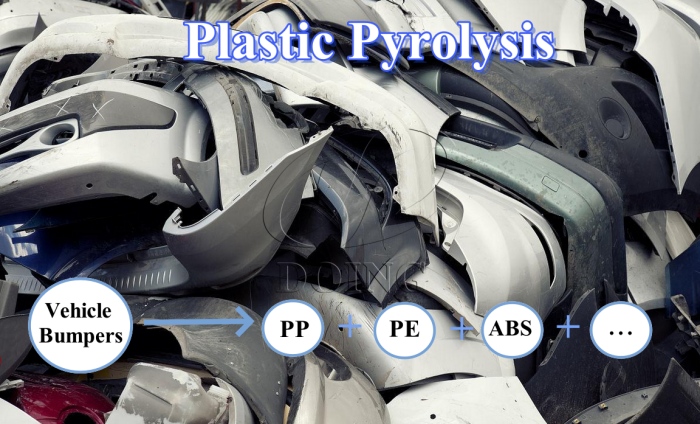

Waste vehicle bumper composite plastic structure for recycling pyrolysis process

Waste vehicle bumper composite plastic structure for recycling pyrolysis process

The structure of the vehicle bumpers is generally made from plastic materials like polypropylene (PP), polyethylene (PE), polycarbonate (PC), acrylonitrile butadiene styrene (ABS), etc. and other enhanced engineering plastics. Therefore, pyrolysis process can be used to convert used vehicle bumpers, which are typically made of plastic materials into valuable products.

2. After pyrolysis, what specific products can customers get from car bumpers recycling pyrolysis plants?

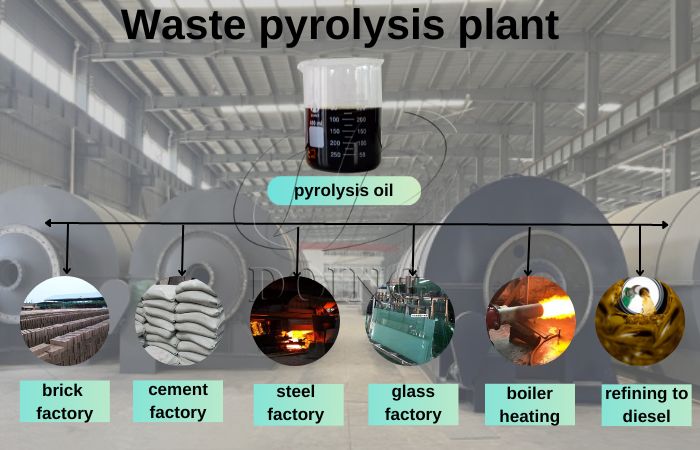

(1)Pyrolysis oil

Pyrolysis oil obtained from vehicle bumper pyrolysis plant is a heating fuel with a very high calorific value and can be used as an alternative fuel to diesel for boilers, cement plants, glass plants, steel plants, etc. It can also be converted into very high purity light diesel by DOING pyrolysis oil distillation plant being done.

Usages of waste plastic pyrolysis oil extracted from vehicle bumper pyrolysis plant

Usages of waste plastic pyrolysis oil extracted from vehicle bumper pyrolysis plant

(2)Carbon black

After pyrolysis, you get raw carbon black, which can be sold directly to cement plants as an additive to make cement. It is also possible to use DOING carbon black deep processing equipment to obtain N440, N550 and other grades of standard carbon black after fine processing of raw carbon black.

(3)Flammable but non-condensable gas

This syngas is similar to natural gas and will be recycled directly into the furnace of the reactor for heating. If customers want to improve their utilization, they can consider storing excess gas and selling it separately as an alternative heating fuel to natural gas.

3. Potential benefits for recycling vehicle bumper by pyrolysis plant

(1)It allows for the recovery of valuable resources from used bumpers, reducing waste and conserving raw materials. The pyrolysis process can generate useful byproducts such as pyrolysis oil, which can be used as a heating fuel source for various boilers, furnaces, heavy oil power plants or further refined into diesel for wider uses, such as trucks, tractors, diesel generators, etc.

(2)It can help reduce the environmental impact of discarded bumpers by diverting them from landfills or incineration.

(3)Pyrolysis plant offers a way to recycle bumpers made from various types of plastic, including those that are difficult to recycle through traditional methods. And it can help us create economic benefits.

Vehicle bumper recycling pyrolysis plant for sale

Vehicle bumper recycling pyrolysis plant for sale

However, it's important to consider that the pyrolysis process requires appropriate infrastructure, expertise, and careful management to ensure efficient and environmentally responsible recycling.

After this introduction, I believe that you have a better understanding of whether the vehicle bumper can be processed by DOING's pyrolysis plant. If you still have questions or want to customize a detailed solution of DOING pyrolysis plant, please leave a message on the DOING website, and a professional business manager will contact you immediately.

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

- What are the types of materials pyrolysis equipment can process?

Leave a message

Mobile/Wechat/Whatsapp: