How is the profitability of a plastic pyrolysis plant?

Plastic pyrolysis, a process that converts plastic waste into valuable products like fuel oil, carbon black, syn-gas, etc., has gained attention as an innovative solution to address environmental concerns and promote a circular economy. One important aspect to consider before investing in a plastic pyrolysis plant is its profitability. This article will explore the factors that influence the profitability of such plants.

Factors Affecting Profitability of Plastic Pyrolysis Plant

1. Cost of Raw Materials:

The availability and cost of plastic waste are crucial factors. Access to a steady supply of plastic waste at a reasonable price is essential for maintaining profitability.

You can cooperate with your local supplier of waste plastics or have a check if there are allowances for waste plastic recycling. Then you could collect waste plastics like, PE(HDPE/ LDPE), PP, PS, ABS, paper mill waste, organic waste, nylon bags, plastic bottles, medical plastic waste, household plastic scrap, etc., all can be recycled by pyrolysis plant.

Recycable waste plastic for pyrolysis plant

Recycable waste plastic for pyrolysis plant

2. Pyrolysis Machine and Operational Expenses:

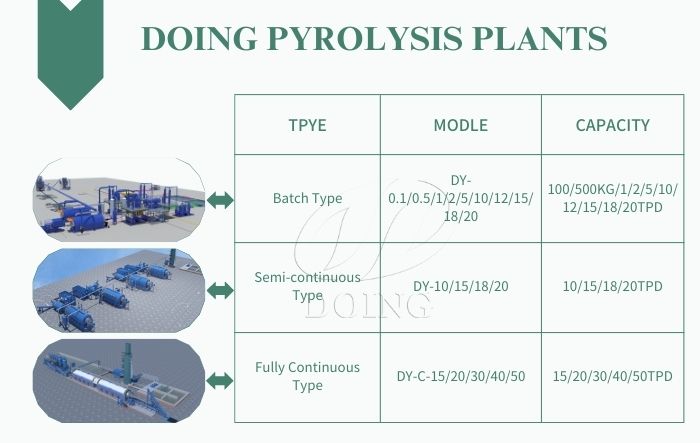

The initial investment in waste plastic pyrolysis machine and the ongoing operational expenses play a significant role in determining profitability. The scale of the plant, the technology employed, and the level of automation can affect both capital costs and operating expenses.

Efficient equipment and streamlined processes help minimize costs and optimize profitability. Henan Doing Company's pyrolysis plants have been hot sale to 100+ countries and regions, and highly praised for its stable running, mature pyrolysis technology, long service life, etc.

Different capacities of plastic pyrolysis plants for sale

Different capacities of plastic pyrolysis plants for sale

3. End Product Sales Prices:

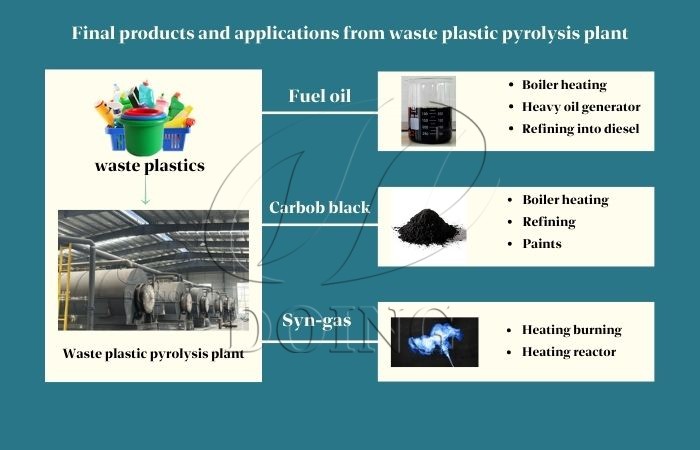

The profitability of a plastic pyrolysis plant relies on the demand and market value of the end products it generates. The quality and quantity of plastic pyrolysis oil, gas, carbon black, or other by-products produced from plastic waste influence their selling price.

DOING plastic pyrolysis machine can effectively convert waste plastic into fuel oil. The final fuel oil can be directly used in heavy industry plants or be refined into diesel by pyrolysis oil distillation plant, etc. Carbon black can be sold or go on deep processing. Syn-gas can be used for heating the plastic pyrolysis machine reactor to save operational expenses.

Plastic pyrolysis plant final product usages

Plastic pyrolysis plant final product usages

4. Environmental Regulations and Incentives:

Government regulations and incentives related to waste management and renewable energy can significantly impact the profitability of a plastic pyrolysis plant. Supportive policies, such as subsidies, tax incentives, etc, can enhance profitability and create a favorable investment environment.

In conclusion, the profitability of a plastic pyrolysis plant depends on various factors. Based on years of waste plastic pyrolysis plant installation experience and customers' feedback, the plastic to oil pyrolysis plant project is indeed a profitable business while contributing to environmental sustainability. Henan Doing Company can help you make a careful planning and customize suitable scale plastic pyrolysis machines to carry out efficient operations. Please feel free to contact us for an inquiry.

Prev:Instructions for building pyrolysis plants in Malaysia

Next:How much energy is required for pyrolysis plant operation?

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

- What are the types of materials pyrolysis equipment can process?

Leave a message

Mobile/Wechat/Whatsapp: