Home>News>Enterprise News>DOING Brand 10Ton Capacity Pyrolysis Distillation plant order from Fiji clients

DOING Brand 10Ton Capacity Pyrolysis Distillation plant order from Fiji clients

On January 5, 2024, Henan Doing Company, a leading provider of environmental waste to fuel energy pyrolysis distillation solutions, has successfully secured a deal with clients in Fiji.

The transaction involves the purchase of two 10 ton capacity pyrolysis plants and one 10 ton pyrolysis oil distillation plant, catering to the recycling and reuse of waste rubber tires and plastics.

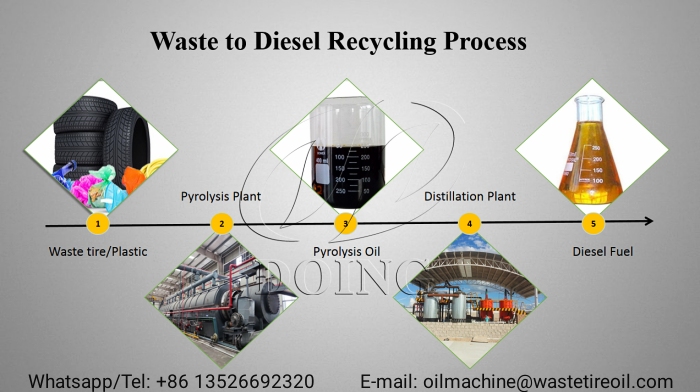

Waste tire plastic pyrolysis distillation process

Waste tire plastic pyrolysis distillation process

The tire plastic pyrolysis distillation plant offered by Henan Doing Company is designed to provide efficient and eco-friendly solutions to the growing problem of waste management. With their advanced technology, these units are capable of transforming waste materials into valuable resources such as non-standard diesel, pyrolysis oil, and carbon black.

Pyrolysis distillation oil applications

Pyrolysis distillation oil applications

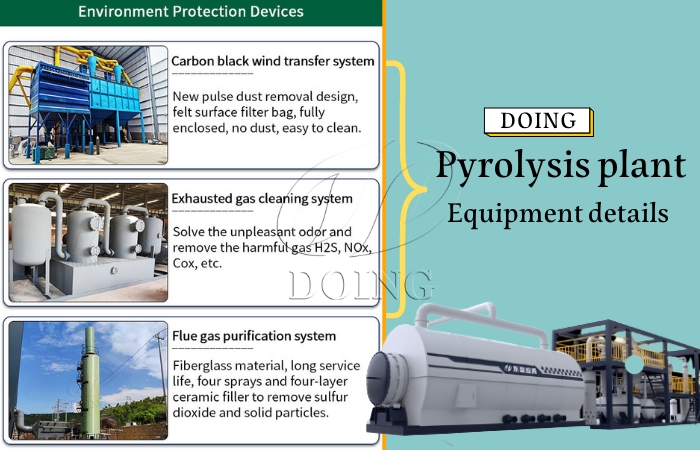

What sets Henan Doing Company apart is the dedicated design of environmental protection devices equipped with pyrolysis distillation plant, a key concern for their clients. Fiji, in particular, has stringent environmental regulations. To alleviate any worries, the client visited us and the operation site of our pyrolysis distillation plant. They were highly impressed by the running site's clean and odor-free facility and the strict emission control measures. This visit bolstered their confidence in partnering with Henan Doing Company for the establishment of a waste to fuel energy pyrolysis distillation plant.

Environmental designs of DOING pyrolysis distillation plant

Environmental designs of DOING pyrolysis distillation plant

With the assistance of Henan Doing Company's sales manager, our Fiji clients successfully completed all necessary environmental procedures for the setting up waste tire plastic pyrolysis distillation plant. The entire process was seamless, and the deal was finalized to the satisfaction of both parties.

The whole production process of 10ton capacity pyrolysis distillation plant is expected to be finished within three months. Welcome to stay tuned to see more delivery information and send us your inquiry to customize suitable waste to fuel energy pyrolysis distillation plants!

Prev:A set of 15TPD waste plastic to oil pyrolysis plant was delivered to India

Next:DOING 15TPD tire pyrolysis machine order from Brazilian client

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line