What’s the working process of the waste oil to diesel recycling plant?

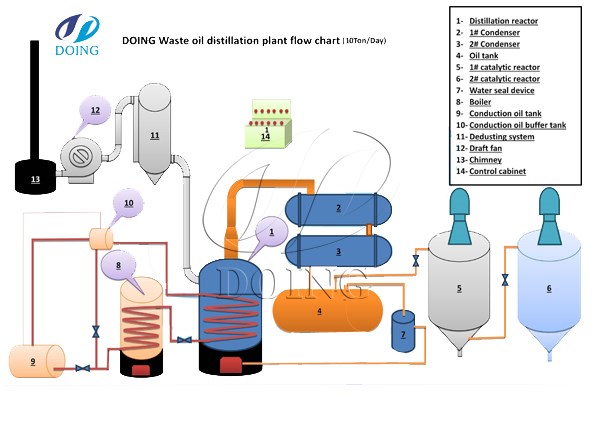

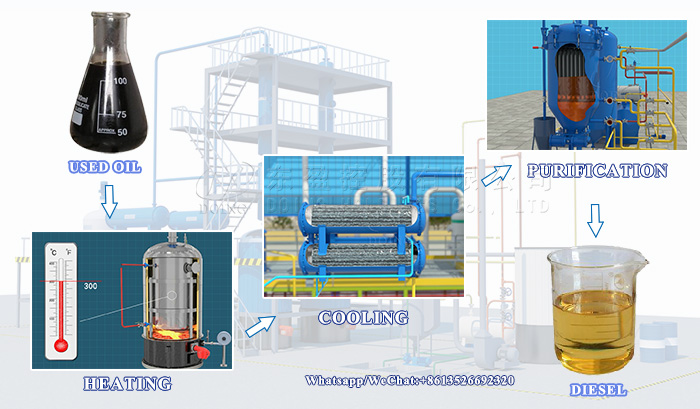

The working process of waste oil distillation machine includes high-temperature distillation, circulation water cooling, catalyst deordorization and clay decolorization, then we can get diesel from waste oil. The waste oil can be refined by Doing Group waste oil distillation machine includes: heavy and black oil, waste engin oil, tire pyrolysis oil, plastic pyrolysis oil, crude oil,etc. Next, let's see the working process of waste oil distillation machine:

1) Heating and distillation:

Firstly, we pump the waste oil to the distillation reactor, then start heat conduction oil preheating system to preheat the entire system;

Secondly, when the temperature of heat conduction oil reaches to a certain temperature, turn on the burner to heat the distillation reactor;

Thirdly, control the temperature of distillation reactor between 380 degrees and 400 degrees, and the oil gas will generate.

The working process of the waste oil distillation plant

The working process of the waste oil distillation plant

2) Decolorization and deodorization:

For this section, now we have two solutions.

Solution I:

Oil gas come out from the distillation process would go to a condenser system to be cooled down to liquid oil at first, then mix with chemicals to remove wax and gum, thus to remove heavy color and smell from the oil, finally to get the clean fuel, which is diesel;

Solution II:

Oil gas come out from the distillation system would be cut into different fractions by temperature control. Firstly, in lower temperature heating, we get the light fraction out and make it directly go to the condenser system to be cooled down to light oil. Then we increase the heating temperature to get the heavy fraction out from the waste oil, and make it go through a catalytic system to be cracked and absorbed color and odor, thus to get the clean fuel.

Working process of waste oil distillation machine

Working process of waste oil distillation machine

Generally speaking,the diesel yield of waste oil distillation machine is 80-85%, and the color is brown yellow. Doing Group waste oil distillation machine has diesel further purification system, which can make further purification for diesel, thus to get light yellow color. For more information about waste oil distillation machine, welcome to consult us feel free.

Prev:How is the profit of the waste oil to diesel refining plant?

Next:What’s the end products application from waste oil to diesel plant?

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

- What are the types of materials pyrolysis equipment can process?

- How can we turn plastic waste into green energy?

- Does it need to add catalysts in the tire plastic pyrolysis process?

- How do you purify tire plastic pyrolysis oil?

- What is the process of converting plastic to diesel?

Leave a message

Mobile/Wechat/Whatsapp: