Home>FAQ>Is it better to put the whole tire directly into the pyrolysis reactor or shred the tires when pyrolyzing waste tires in Australia?

Is it better to put the whole tire directly into the pyrolysis reactor or shred the tires when pyrolyzing waste tires in Australia?

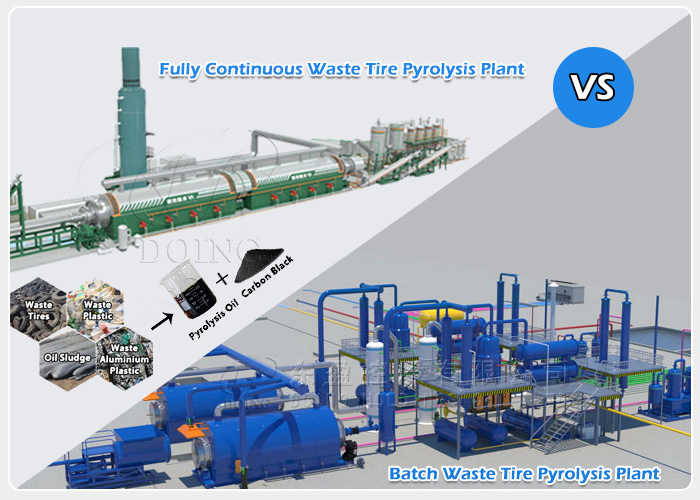

Previously, people can adopt two kinds of waste tires pyrolysis machine in Australia, one was the batch type waste tires pyrolysis machine and the other was full continuous type waste tires pyrolysis machine. For batch type waste tires pyrolysis machine, people can directly put the whole tire directly into the pyrolysis reactor; for full continuous type waste tires pyrolysis machine, it was necessary to shred the tires and process them into powder so that the machine can continuous feeding and discharging slag and the processing volume and efficiency was higher.

Fully continuous and batch type waste tires pyrolysis machine

Fully continuous and batch type waste tires pyrolysis machine

But recently, according to feedback from our regular Australian customer, the local government requires that the tires must be shredded before being pyrolyzed no matter by batch type or full continuous type waste tires pyrolysis machine now.

After he saw the policy of the local government, he planned to order a waste tire shredding machine from us. Because the Australian customer has purchased waste tire pyrolysis machine from us before, the customer knew well about the Doing Company's equipment manufacturing strength, and the technology and quality of equipment is guaranteed.

Waste tire shreder machine

Waste tire shreder machine

Our waste tire shredding machine can shred many kinds of waste tires into 3-8cm blocks and the waste tires blocks can be more completely pyrolyzed and the processing efficiency can be improved, so it’s a perfect match for both batch type and full continuous type waste tires pyrolysis machine.

If you want to know more information about Australian waste tires pyrolysis market, or don’t know how to choose a suitable design and configuration of our waste tires pyrolysis machine and waste tires shredding machine, please feel free to contact Henan Doing Company at any time. Our engineer team can offer you professional solutions.

Prev:Which oil can be used as a substitute for residual fuel oil and how can it be obtained?

Next:Can waste tire pyrolysis plant industry bring great value?

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line