What's the pyrolysis process of producing fuel from polypropylene plastic?

Polypropylene plastic(PP Plastic) is the most versatile general-purpose thermoplastic and, therefore, accounts for the largest share of plastic waste. In order to improve the resource utilization rate of waste plastics, the plastic pyrolysis plant can be used to turn polypropylene plastic into fuel. So what is the pyrolysis process of polypropylene plastic to produce fuel? Here I will explain it in detail.

How to convert polypropylene plastic to fuel oil?

How to convert polypropylene plastic to fuel oil?

The waste polypropylene plastic to fuel pyrolysis process uses the principle of pyrolysis to convert high molecular compounds into a variety of low molecular compounds. Plastic pyrolysis plant can break the polyolefin macromolecular chain of polypropylene plastic, thereby decomposing it into small molecules. Therefore, waste plastic is pyrolyzed into oil and gas through our plastic pyrolysis plant at low temperature.

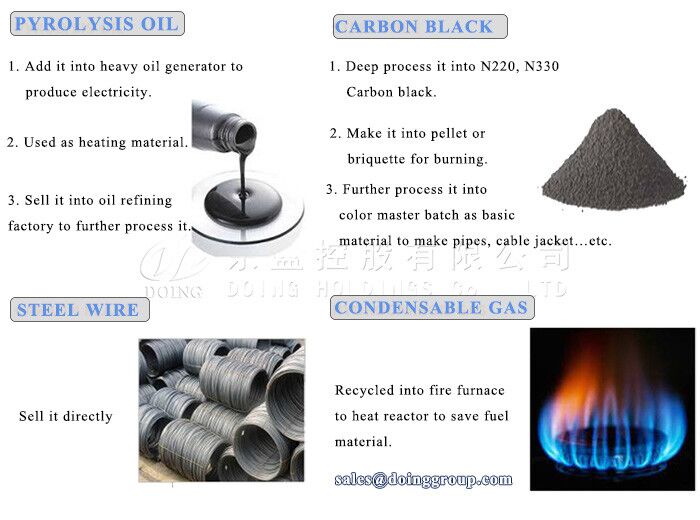

The oil and gas are cooled into liquid oil through a cooling system, and finally oil and carbon black are obtained. And the non-condensable combustible gas will be further purified then directly used to heating the pyrolysis reactor and the exhausted gas will be purfied by our environmental protection devices and be emissied.

The final product

The final product

This polypropylene plastic oil can be used as fuel in various heavy industrial plants such as steel plants, cement plants, boiler plants, power plants or some agricultural equipment. But if your country has less heavy industry, then you can further refine the oil into non-specified diesel through our distillery, distill the oil to remove paraffin and gum, then decolorize and deodorize, and finally get diesel. This diesel can be used in diesel generators, heavy machinery, engines, boilers, etc.

After more than 11 years of exploration and technology update, the pyrolysis efficiency of DOING plastic pyrolysis plant has further improved. And through the unique four-stage cooling system, the oil yield of pure polypropylene plastic can reach 90%. There is no doubt it can create great profits for you.

If you want to get fuel oil from polypropylene plastic or other kinds of waste plastics like PE, PS, ABS, etc. and know more details about our plastic pyrolysis plant, please consult us for free.

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

- What are the types of materials pyrolysis equipment can process?

- How can we turn plastic waste into green energy?

- Does it need to add catalysts in the tire plastic pyrolysis process?

Leave a message

Mobile/Wechat/Whatsapp: