Can plastic bags be recycled into oil?

Plastic bag is a kind of high molecular polymer (or synthetic resin). Under certain conditions, the macromolecule with unsaturated bonds will break, thereby decomposing pyrolysis oil, solid carbon black and combustible gas. Therefore, plastic bags can be recycled into oil.

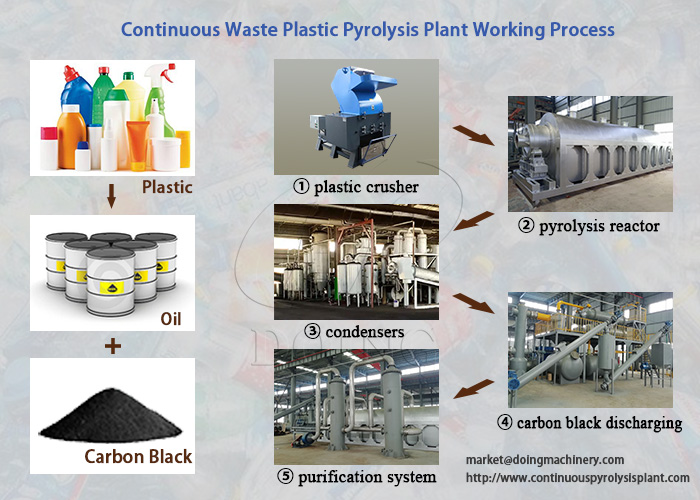

This recycling process from waste plastic bags to oil, called pyrolysis, is well established and widely used. The specific process flow of plastic bags to oil is as follows:

The process of waste plastic pyrolysis plant

The process of waste plastic pyrolysis plant

First, the waste plastic bags are fed to the pyrolysis reactor of the waste plastic pyrolysis plant, and then the pyrolysis reactor is heated with fuel. After reaching a certain temperature, oil gas will be generated, and then the condensable gas will be cooled into oil through DOING's three-stage condensation system, and the non-condensable gas (syn-gas) will be purified and used for heating the pyrolysis reactor to save cost. Cool the waste plastic pyrolysis reactor, and discharge the carbon black for collection.

In addition to plastic bags, PE/PP/PS plastics, ABS engineering plastics, plastic cable sheaths, plastic household waste, medical waste, paper mill scraps, etc. seen in daily life can be recycled into oil, and their oil output ranges from 40-90% overall.

Different plastic materials oil output ranges

Different plastic materials oil output ranges

The plastic oil obtained after the pyrolysis of waste plastics can be used as industrial fuel for heating in boiler rooms, steel plants, cement plants, etc., and can also be further refined into light diesel oil for generators, burners, and heavy agricultural machinery by our waste oil distillation plant; and carbon black can be further used for briquetting for combustion or fine grinding for further processing, and can also be sold directly.

Henan Doing Environmental Protection Technology Co., Ltd. focuses on the R&D and technological innovation of waste plastic/tire/aluminum-plastic/oil sludge/coal tar oil pyrolysis plant. With years of technical precipitation, innovative design concepts, and rich design experience, we have won a global reputation and are trusted by customers in more than 100 countries and regions. Welcome to consult and get favorable quotations of pyrolysis plants!

Prev:How to make fuel and gas out of plastic waste?

Next:What machine can upgrade the color and quality of tire plastic pyrolysis oil?

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

Leave a message

Mobile/Wechat/Whatsapp: