12T waste tyre pyrolysis plant project in Serbia

On March 8, 2020, one set 12T waste tyre pyrolysis plant was successfully installed in Serbia. It is now officially in production. This client has been engaged in recycling waste tyres and waste plastics for a long time. When he learned that the tyre pyrolysis project had a promising future, he began to investigate the project and successfully installed one set waste tyre pyrolysis plant.

12T waste tyre pyrolysis plant installed in Serbia

12T waste tyre pyrolysis plant installed in Serbia

He came to DOING for an inspection last December. During his investigation, He saw the scale of DOING and its standard operating procedures. In addition, he also did a detailed consultation and understanding of the environmental aspects of the waste tyre pyrolysis plant. For example, in terms of waste water treatment, DOING company adopts recycled water, and there is no waste water discharge in the whole process of waste tire treatment; Waste residue treatment: waste tyre pyrolysis plant produced by DOING company adopts a unique black carbon emission design, which is pollution-free in the whole operation process.

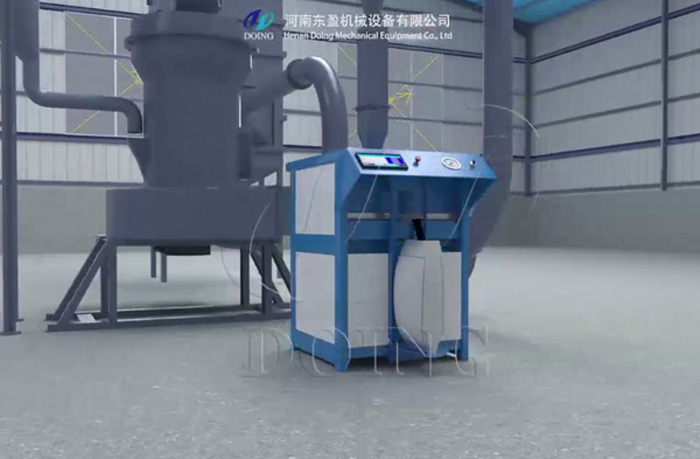

Unique black carbon emission design

Unique black carbon emission design

After the inspection, he signed a contract to buy one set waste tyre pyrolysis plant. In the production process, DOING factory is strict with the quality, and from the selection of materials to the process are all according to the standard process. Under the joint efforts of the factory division and the manufacturing workers, the waste tyre pyrolysis plant was finished according to the time. Then DOING company arranged the vehicle to deliver the 12T waste tyre pyrolysis plant from DOING factory to Serbia.

DOING factory

DOING factory

When waste tyre pyrolysis plant arrived in Serbia, DOING company sent experienced installation master to guide the installation. The following is a picture of the waste tyre pyrolysis plant being installed.

Waste tire pyrolysis plant was being installed

Waste tire pyrolysis plant was being installed

As a manufacturer with 10 years of experience, we DOING company not only provide quality equipment, but also provide on-site installation of after-sales service, so that customers have no worries. At present, the 12T waste tyre pyrolysis plant has been put into operation, which can produce 4.8T tire oil one day. If you are interested in our waste tyre pyrolysis plant, please feel free to contact us at any time.

Prev:12TPD plastic to oil conversion pyrolysis plant is being installed in India

Next:12TPD plastic to oil conversion pyrolysis plant project in Indonesia

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line

Leave a message

Mobile/Wechat/Whatsapp: