Affecting factors for the oil yield of waste plastic pyrolysis plant

Nowadays, more and more people come to consult our waste plastic pyrolysis plant. According to our statistics, most customers are most concerned about the problem of the oil rate of the equipment. So what problems should be paid attention to, and can improve the oil yield of the waste plastic pyrolysis plant?

Waste plastic oil yield problem

Waste plastic oil yield problem

First of all, the water content in the waste plastic should not be too much. As we all know that the input quantity to a pyrolysis plant is certain, of course the higher water content, the less oil output.

The second is the proper temperature control during the waste plastic pyrolysis plant working process. Choosing our waste plastic pyrolysis plant, we have a team of professional engineers to provide you with one-on-one on-site instructional installation services, including a complete set of equipment operation instructions, as well as a detailed temperature control process. Through the professional temperature control guidance of our engineers, can help you get the highest oil output rate from waste plastic.

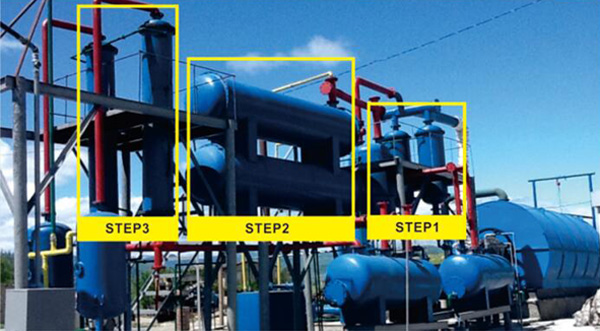

Finally, and most importantly, the choice of a high-quality waste plastic pyrolysis plant supplier, the so-called high-quality equipment supplier, that is, the equipment's condensing system must be good. Our condensing system uses the most advanced 3-stage condensing system in the oil and fat industry, which guarantees you the best oil output based on the above three points.

DOING company 3 stage cooling system

DOING company 3 stage cooling system

a>. The first-step condenser adopts vertical design to replace the previous horizontal cooling pipe, which can reduce the pressure of the oil outlet and avoid the block of the heavy oil inside the first-step condensers.

b>. The second-step condenser is the most important of the three-step condensations, using a horizontal design with many small tubes inside to make the biggest contact area of the oil gas with cooling water, here 90% of the oil and gas will be cooled in this condensing device.

c>. The last-step condenser, the vertical designThe gas goes from bottom to top, the speed is slow, so the oil and gas can be cooled sufficiently. It is the additional condenser to the cooling system, which is mainly set up to avoid extra oil gas wasted when workers make fire too big and oil gas come out too fast.

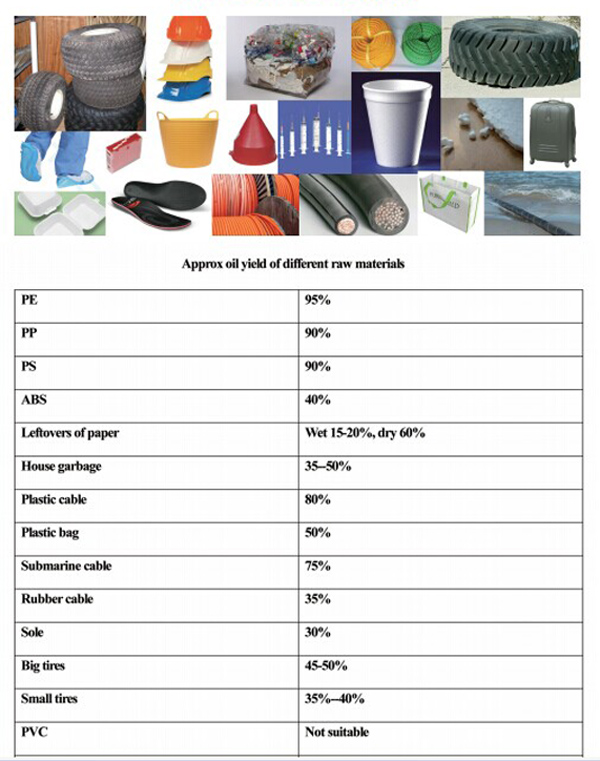

Different kinds waste plastic oil yield

Different kinds waste plastic oil yield

At last, of course different kinds plastics have different oil yield, below we sort out some different kinds plastics with different oil yield, their oil yield for your reference!

DOING waste plastic pyrolysis plant

DOING waste plastic pyrolysis plant

If you want to investment in our waste plastic pyrolysis plant, welcome to tell us your specific kind of waste plastic, we can analysis the oil yield for you.

Prev:DOING Company sincerely invites you to visit the International Trade Fair in Lagos!

Next:2 sets 10T/D waste plastic pyrolysis plant installed in Dali, Yunnan

Tyre pyrolysis oil is increasingly used as industrial fuel in the market, but unrefined tyre pyrolysis oil contains a lot of impurities and is not effective, so it is better to be distilled to improve the quality of the oil.

Waste oil refining plant is specially designed for waste oil and pyrolysis oil to diesel. This whole refining process includes distillation, cooling, decoloring and deodoring system.

DOING company is strong and has other different processing capacity equipment to choose from, 500kg, 1T, 3T, 5T, 10T. , 12T, 15T, 30T, 50T, 100T, and so on. Compared with these large capacity equipment, small plastic to fuel machine also has its unique ad

Please feel free to leave your contacts here and your privacy is protected. A competitive quotation will be provided according to your detailed requirement within one business day.

- QWhat raw material do you plan to process?

- Rubber tire

- Waste plastic

- Oil sludge

- Biomass

- Waste oil

- Pyrolysis oil

- Not decided yet

- Other:

- QMachine daily processing capacity (tons of feedstock)

- 100kg-2ton

- 5-15ton

- 15-50ton

- >50ton

- Not decided yet

- QDesired final product and its primary applications

-

Tel/WhatsApp: 0086-135-2669-2320

Tel/WhatsApp: 0086-135-2669-2320

-

Phone: 0086-371-5677 1821

Phone: 0086-371-5677 1821

-

Skype: bonniezhao2

Skype: bonniezhao2

-

E-mail: sales@doingoilmachine.com

E-mail: sales@doingoilmachine.com

- Is pyrolysis better than incineration?

- What are its plastic pyrolysis benefits compared to traditional plastic recycling methods?

- How pyrolysis technology helps reduce the carbon footprint?

- Can you get money out of old tires?

- What is the Most Profitable Plastic Recycling Way?

- How to Set Up a Tire Pyrolysis Recycling Business?

- Why is PET and PVC not suitable for pyrolysis?

- How much oil gas is generated during the pyrolysis of plastics?

- How to Improve the Quality of Plastic Pyrolysis Oil?

- Equipment composition of waste plastic oil pyrolysis production line